Doouble-end Tenoner Series

- Product Details

- Company Profile

Doouble-end Tenoner Series

| Doouble-end Tenoner Series | |

| Feature | |

| With the jumping device in the scoring saw and the first milling unit, can prevent tearing effectively when processing | |

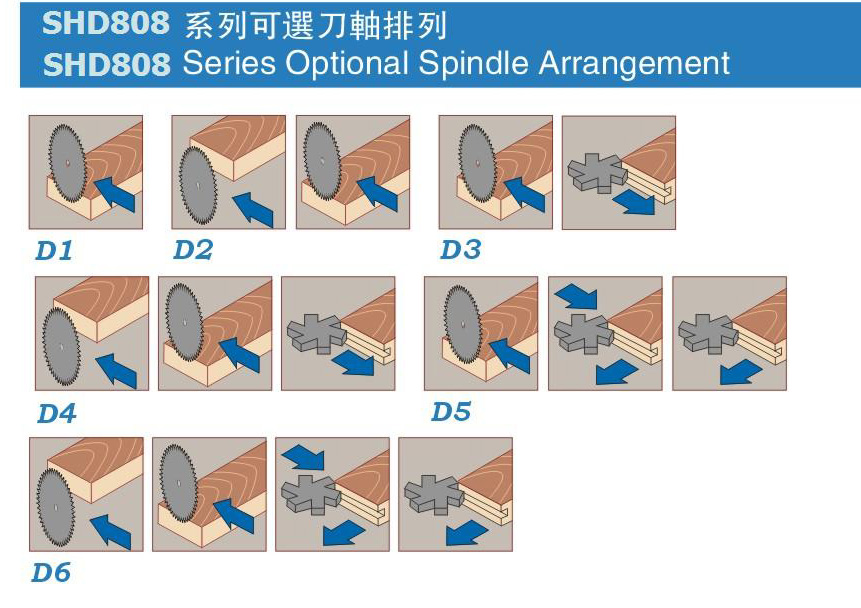

| Each spindle can rotate, convenient to achieve angle-truncate, tenon, groove and etc. | |

| Adopted widen by high precision linear orbit, machine can run in precision and wearable. It assure the precision when widen the working size, also can guarantee to fit your highly requirement for setting the working width. | |

| Orbit lubrication can reduce the frictions of slide when moving, increase the nature life of orbit as well. | |

| The cut-off saw equiped 4KW(11KW) motor and can be installed hoggers, which is quite suitable to process the big cutting capacity materials. | |

| Much better to infeed the big size panels with the lengthen chain belt design | |

| Supported with the roller bearing in the feeding belt, make the movement more stable and reduce the noise | |

| In order to assure every chain board with high precision, we use the high hardness cast iron and treated with high temperature and maching by CNC | |

| Each spindle is equired with high precision bearing, spindle speed of milling units reach to 7500r/min(9000r/min) | |

| Each spindle is configureed with read out, can display the position of spindle veracious. | |

| Adopted inverter for feeding, make the feed speed reaches to 5-25m/min (40m/min), increase the productivity | |

| Adopted touch screen makes the operation convenient, rapid and visualized, reduce the labor intensity and time, improve efficacy. | |

| Adopted the high class electric component to build up the perfect electic system can increase the stabilization | |

| Setting all of the parameter by PLC, easy to view and control. Reduce labour and the time for setting parameter, improve the produdctivity effectively. | |

| Through the automatic locking which controlled by PLC, can lock the linear orbit automatically. No only can reduce the labour but also can assure the stable of the machine base, improve the quality of the work pieces. | |

| Adopted excellent material to make of the pressure belt, keep good wearable. | |

| Only input value of working width and thickness to the PLC, you can control the width and thickness. Precision of setting width is 0.1mm. Easy to locate the workpieces and convenient to operate | |

| Sealed safety enclosure is controlled by pneumatic, can reduce noise levels, improve extraction and operator safety. | |

| Model | SHD808 |

| Working Width | 250/2500mm |

| Working Thickness | 6/120mm |

| Cutting circle(min-max) | |

| Left saw unit | 125-200mm |

| Right saw unit | 125-200mm |

| Left cut-off saw | 250-300mm |

| Right cut-off saw | 250-300mm |

| First left and right unit | 140-160mm |

| Second left and right unit | 140-160mm |

| Spindle diameter | |

| Left saw unit | 25.4mm |

| Right saw unit | 25.4mm |

| Left cut-off saw | 30mm |

| Right cut-off saw | 30mm |

| First left and right unit | 40mm |

| Second left and right unit | 40mm |

| Cutterhead length | 100/175mm |

| Basic motor powers | |

| Left saw unit | 2.2KW 3KW/4HP/3HP |

| Right saw unit | 2.2KW 3KW/4HP/3HP |

| Left cut-off saw | 4KW 11KW/15HP |

| Right cut-off saw | 4KW 11KW/15HP |

| First left and right unit | 2X5.5KW/7.5HP |

| Second left and right unit | 2X7.5KW/10HP |

| Feed (Inverter) | 4KW/5HP |

| Pressure belt lift | 2X0.18KW/0.24HP |

| Widen (Inverter) | 0.37KW/0.49HP |

| Total motor power | 78KW/43.13HP |

| Feed speed | 5-25m/min |

| Spindle speed | 7500r/min |

| Dust pipe diameter | 120mm |

| Overall machine dimensions | 4300x4000x1950mm |

| Weight | 5800kg |

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier