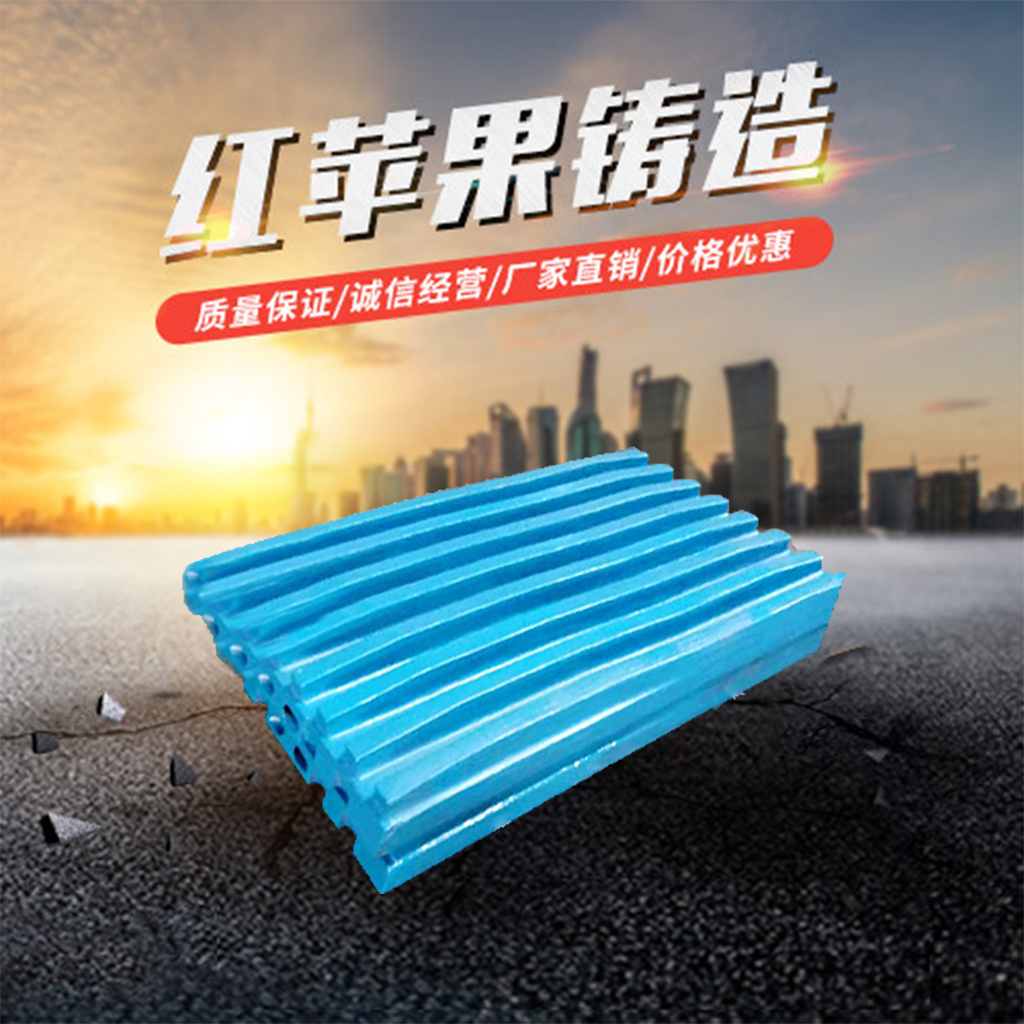

Crusher jaw plate

- Product Details

- Company Profile

Crusher jaw plate

Commonly used aliases: e plate (moving jaw plate, static jaw plate), tooth plate, high manganese steel jaw plate, ultra-high manganese steel jaw plate, composite alloy jaw plate, wear-resistant jaw plate, jaw crusher jaw plate.

Main materials: high manganese steel (Mn13,Mn18), manganese chromium alloy (Mn13Cr2,Mn18Cr2), etc.

Casting process: v method, lost foam, sodium silicate sand casting.

Applicable materials: River pebbles, granite, basalt, iron ore, limestone, quartz, diabase, iron ore, gold, copper, etc.

Scope of application: sand and gravel yard, mining, coal mining, concrete mixing station, dry powder mortar, power plant desulphurization, quartz sand and so on.

The tooth plate of the jaw crusher is referred to as the jaw plate, which is divided into fixed jaw plate and movable jaw plate, which is the main part of the jaw crusher. In the running state of the jaw crusher, the moving jaw is attached to the movable jaw plate to do compound pendulum movement, which forms an angle with the fixed jaw plate to extrude the stone. Therefore, it is a relatively easy to damage accessories in the jaw crusher.

The jaw plate is a wear-resistant accessory inside the jaw crusher. The early jaw plate is made of cast iron and ordinary hardened steel. The jaw plate of this material has poor wear resistance, low hardness, poor toughness and easy fracture, so its service life is short.

With the progress of the times and technology, the jaw plate made of high manganese steel has appeared on the market, which has good wear resistance and greatly improves its service life.

The jaw plate (tooth plate) is not only an important part of the main engine of the jaw crushing station, but also its main vulnerable parts, because the jaw plate (tooth plate) is a part that is in direct contact with the material when the jaw crushing station is working.

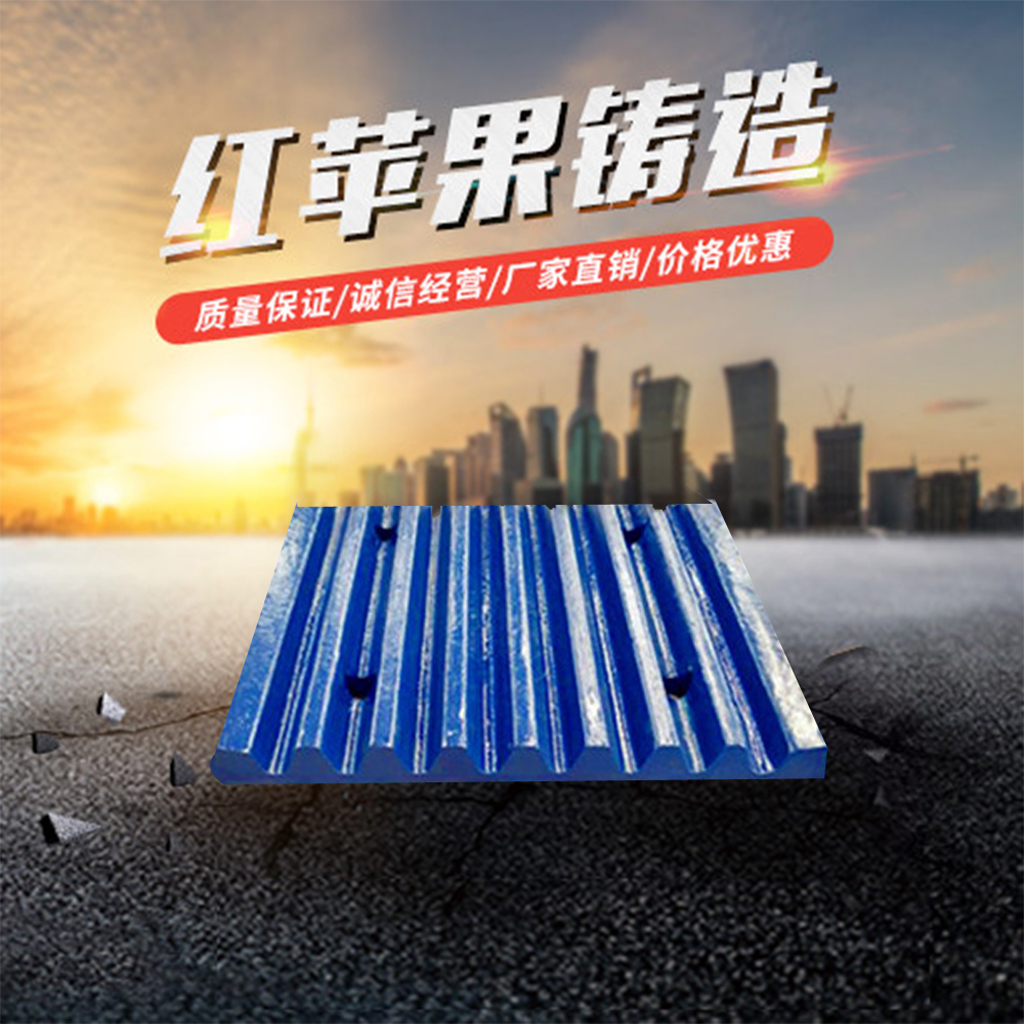

High manganese steel jaw plate

High manganese steel is the traditional material of E plate of E type crusher. it has good toughness and good deformation hardening ability. The use of materials: Mn13, Mn13Cr2, Mn18Cr2 (that is, ultra-high manganese) or special ingredients according to working conditions, Zhangjiakou red apple casting jaw crusher E plate, exquisite workmanship, rigorous ingredients, heat treatment in place, E plate service life is more than 50% more wear-resistant than similar products.

Medium manganese steel jaw plate.

Due to the low initial hardness and yield strength of high manganese steel, the work hardening of high manganese steel is not sufficient and it is easy to be rheological and cut under the condition of non-strong impact. In order to improve the service life of E plate, medium manganese steel was developed. When dealing with softer materials, the effect of medium manganese steel is better. When the medium manganese steel jaw plate is crushed limestone on a small crusher, the service life of medium manganese steel is about 185% of that of high manganese steel.

Bimetal composite jaw plate

According to the working principle and practical application status of jaw crusher, a kind of double liquid bimetal composite casting jaw plate is developed. the working face adopts alloy steel with high wear resistance and the lining adopts cast steel with good impact toughness. give full play to the strengths of all kinds of materials. At the same time, the special gating system and casting process ensure the uniformity and integrity of the composite interface, so that the performance of the E plate can be optimized.

Low alloy cast steel plate

Medium carbon low alloy cast steel is a kind of wear-resistant material widely used at present, mainly because of its high hardness and proper toughness, which can resist the cutting action of the material and the fatigue spalling caused by repeated extrusion. therefore, it shows good wear resistance. At the same time, through the adjustment of composition and heat treatment process, the hardness and toughness of medium carbon low alloy cast steel can be changed in a wide range to meet the requirements of different working conditions.

Red Apple Machinery and equipment Manufacturing Co., Ltd., specializing in the production of high manganese steel, high chromium cast iron, carbon steel, alloy steel and other casting products. The company is located in Zhangjiakou City, Hebei Province, the host city of the Winter Olympic Games, adjacent to the capital Beijing. It is the intersection of the Beijing-Tianjin-Hebei economic circle and the Ji-Jin-Meng economic circle around the Bohai Sea. The logistics is convenient to Tianjin Port, Tangshan Port and Huanghua Port. The company's industrial plant is 25000 square meters, with an annual output of more than 3000 tons; the company's casting technology: water glass sand casting, lost foam casting, film-coated sand precision casting. The main production equipment: 4 sets of 1-3 tons medium frequency electric furnace, 3 sets of heat treatment circuit, 12 sets of lifting equipment. Main processing equipment: 1 CNC milling machine, 1 gantry washing machine, 1 CNC lathe, 2 CNC plasma cutting machines. Main testing equipment: direct reading spectrometer, high frequency infrared carbon and sulfur analyzer, metallographic microscope, tensile testing machine, hardness testing equipment, coloring testing, magnetic particle testing, ultrasonic testing equipment. Production capacity: the weight of a single product ranges from 1 kg to 3 tons.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier