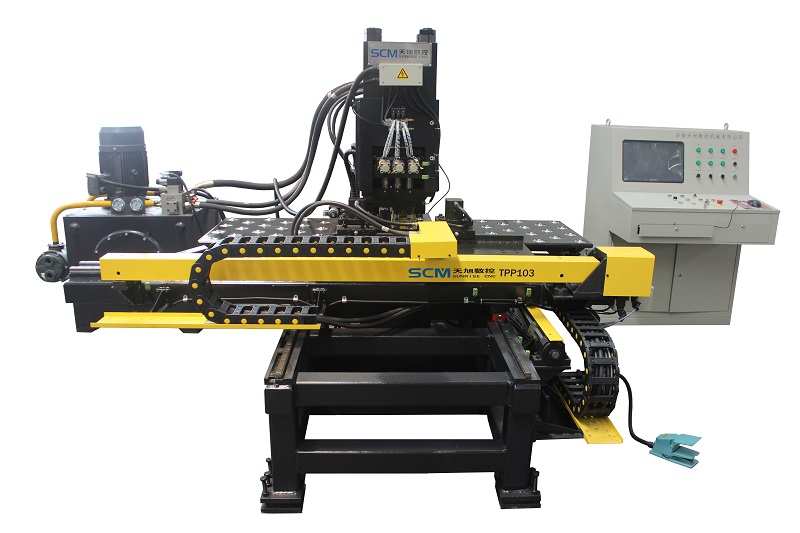

TPP103 CNC PLATE PUNCHING MACHINE

- Product Details

- Company Profile

TPP103 CNC PLATE PUNCHING MACHINE

Special CNC machine for punching and marking of steel plates in the field of steel tower industry. It is also used to punch and mark of steel plates of other industries.

Product Feature:

1. The machine-frame is made by C-type plate welding, with good rigidity and big handling space. The machine sets three die-stations (two punching, one marking), automatic switching die-stations. Clamping system can be adapted to different workpiece, with reference block, and workpiece supported by rolling-ball working table. X & Y axis action controlled by servo motor and ball-screw driving and PLC, control the position of punching, so as to make the whole machining process automatically. Operator input the workpiece program, it can be used repeatedly

2. Adopt CNC technology, servo motor infeeding, with high efficiency, stable workpiece precision.

3. Important functional components adopt modular assembly, easy to repair it.

4. Achieve punching and marking on the one plate.

5. Easy programming, can read CAD drawing and also can use the program generated by lofting software. It can ready TEKLA lofting software files, such as NC1 format.

6. With self-diagnosis failures function.

7. X, Y axis are driven by servo motor + ball screw + linear guide, the precision is better.

Special advantages:

1. Hydraulic station adopts dual-pump and single motor. Punching speed is faster than other company’s, so it is more efficient and improve the workshop ability.

2. It adopts sleeve-type coupling for all pipelines, which avoid leakage. The main communication cable is shielded twisted pair cables world famous brand, which works well in resisting interference.

Model | TPP103 |

Max size of work piece L×W(mm) | 1500×800 |

Max. diameter of punching (mm) | Φ26 |

Plate thickness of punching (mm) | 5~25 (Q 235) |

Punching force (KN) | 1000 |

Marking force (KN) | 800 |

Min. distance between hole and plate edge (mm) | 25 |

Dimensions of characters (mm) | 14×10×19 |

Quantity of character | 12 |

Die-stations | 3 |

Programming mode | Auto CAD or lofting software |

Overall dimensions L×W×H (mm) | About 3200×3000×1900 |

Net Weight(kg) | About 5420 |

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier