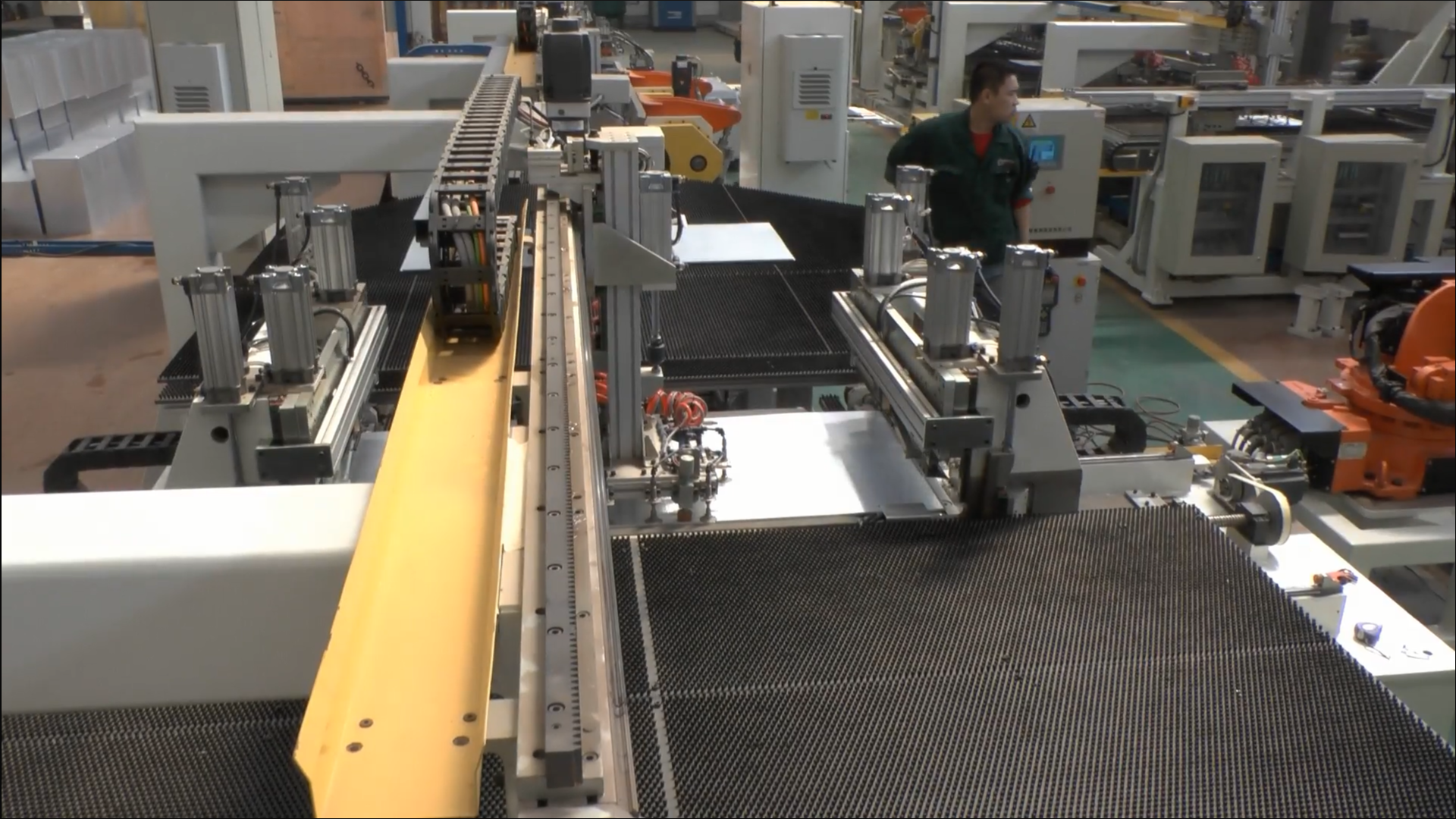

Automatic production system for inner liner of chest freezer

- Product Details

- Company Profile

fully automatic production without operators, high speed and capacity in output of the products, high quality guaranteed , fully automatic changeover in one minutes.

Production capacity :

Out put production one inner liner in 20 seconds.

Model change in metal line and assembly line 60 seconds, min loading quantity for each model will be 50-100pcs.

Model change for winding section: in case of difference in width and length within 100mm, it is 60 seconds. in all other cases, due to the complete plug change, it is 3-4min.

Note: it is understood that the real total capacity of the plant is depaneding of the real model change during the two shifts.

The inner liner jointing area will consider the glue and the glue specification currently according to the specification from haier.

The glue area will consider to tapping the adhesive belt automatic and manually in separate area.

The winding station adopts the manual pick up the inner liner to the centering table, and automatically load and unloading the inner liner to the forming plugs.

Buffer area adopts the automatic system, with the buffing quantity about 900-1000 pcs, buffering inner liner model consider 12 models per day, and model identification adopts the automatic system.

Copper and aluminum pipe welding adopts the resistance welding machine as specified in the following proposal, and manual insert the pipe, automatically welding the pipe.

Bottom plate corner flanging design is following the design from KingPower with a proper way to ensure the forming quality.

Description of the production cycle

The production cycle foreseen is the following:

Automatic production of the inner liner left side

Automatic production of the inner liner right side

Automatic assembly of the left and right sides

Automatic production of the bottom part.

Automatic assembly of sides and bottom

Control of the parts in positioning

Automatic first clinching operation by 6-8 small points

Automatic gluing positioning

Automatic final assembly of inner tank operation

Manual control , water discharging pipe fixing , tape application

Automatic tube winding on the inner liner whit manual loading/ unloading.

Pipe welding whit automatic machine whit manual loading/unloading

Note: in order to guarantee the proper mixing of the production, according to the requirements of the foaming line, we suggest that between inner tank assembly area and winding area shall have the buffer of the inner tank with min quantity 600-800pcs on storage. The buffering storage adopts the automatic system.

Equipments

The total equipments used in the plant are (see the relevant lay out):

Automatic line for left side inner liner production

Automatic line for right side inner liner production

Automatic line for bottom production

Automatic machine for side parts assembly

Automatic machine for cabinet and bottom assembly

Automatic shuttle system for clinching lines loading

Automatic clinching line

Conveyor

Automatic winding machine

Welding machine

Automatic buffer storage

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier