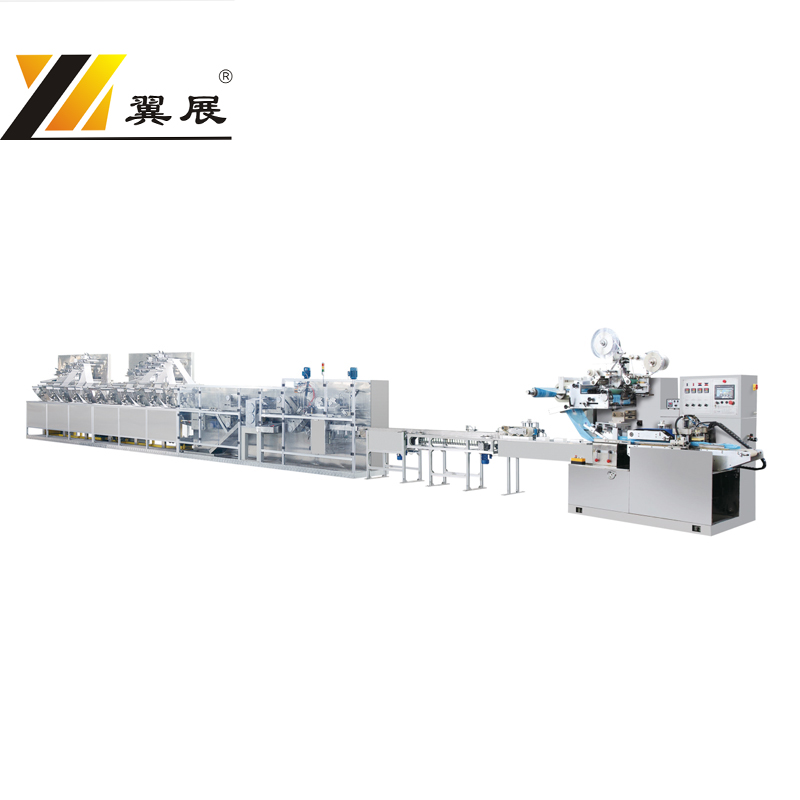

YZCD-1828 Full Automatic wet tissue machine

- Product Details

- Company Profile

The Flowing chart of full-auto wet tissue machine is: Raw material—splitting —folding— moisture—cutting—pile counting— transport —packing - finished product. All processes (from raw material to finished production) are finished on the machine. It is sanitary during the producing processes, the speed is high and the function is very steady!

Introduce:

The Flowing chart of full-auto wet tissue machine is: Raw material—splitting —folding— moisture—cutting—pile counting— transport —packing - finished product. All processes (from raw material to finished production) are finished on the machine. It is sanitary during the producing processes, the speed is high and the function is very steady!

For wet wipes can be baby wipes. Kitchen wipes, daily cleaning wipes, car wipes, it is depend on your need, the different just the liquid used.

Remark: The glue machine and one more small labor system, 90 degree corner of the machine are for option. It depends on customer’s requirement.

Technical parameter:

Main technical parameter of the folding part: | |

Motive factor | 16KW |

Power supply | 380V, 50HZ |

Suitable material | Spun-lace non-woven fabrics, Hot-rolling non-woven fabrics. |

Unfolded size | (150-230)*(150*250)mm (L*W) |

Folded size | (150-230)*(90-120)mm (L*W) |

Production speed | 1200-1500pcs/min |

Sheets in one bag | 20-100sheets, can be changeable |

Raw material size | 1000-1500mm |

Folding way | Longitudinal Z-folded,Non pop up |

Counting way | Auto-counting, quantity changeable pile system |

Humidification agitating system | Double agitating drums with agitator |

Control system | PLC control system, color touching screen |

Machine size(mm) | 8150*3150*2000(L*W*H) |

Liquid tank capacity | 400 liter, 1tank |

Water tank size(mm) | 2000*1100*1900 250KG |

Weight of machine(kg) | 8000KG |

Option (should add extra cost) | 90 degree or U Turn corner for the connect of folding machine and packing machine. |

Main technical parameter of packing part: | |

Power supply | 380V, 50HZ |

Motive factor | 6KW |

Production speed | 30~50 packages/min |

Production size (mm) | (200-350)*(90-120)*(30-80)(L*W*H) |

Controllable package making machine | Insert angle equipment |

Electric auto-follow, date printing, punching, labeling | |

Control system | Color touching screen, PLC control system. |

Packing film | PE&PET, OPP&PE |

Net weight of machine | 1700KG |

Machine size | 5280*1000*2100 mm (L*W*H) |

Option | The small label system. |

Main Configurations:

The cover of machine and the part with touch with the liquid is make by stainless steel (304 stainless steel).

Raw material:1.Paper size: Max width: 1500mm, Dia of the roll is 1000mm, Paper core 76mm.

2.Packing film size: Max width:370mm, Dia of the roll:500mm, paper core 76mm.

Longitudinal Z fold,. The width of the tissue can be adjusted on the machine in the range.

Pull tension adjuster

Slitting system. There are two slitting part behind the machine, the width of tissue can be adjusted.

Short cut length can be adjusted.

Counting system. Japanese technical.

Lotion supplying system, including two tank with continuously agitators mixing, recycle unit, lotion applicator sucking, liquid from the tank and spraying liquid to the product continuously with adjustable amount.

Liquid come out from holes, more or less liquid can be controlled by the machine, similar as water faucet control.

One the tissue paper, each pcs add the liquid.

It is pillow type packing, 4 temperature controlled system for the sealing system.

Date printing system: such as production date, and Exp date printing, Ink printing type, it will be more clear.

Bag film unwinding, auto unwinder with tension control.

Punching system for the packing film. (open the window for the package).

Label supply, adopted auto unwinder with tenstion control.

Full transfer system, from the folding part to packing part, it can controlled by sensor. Less labor required.

Bag forming applicator, bag film wrap the stacked products, the size can be adjusted. If requires size are big difference, the unit much be changed.

Bagger has individual control system with operate interface, which is connected to main machine for control system.

MISUBISHI PLC control system.

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier