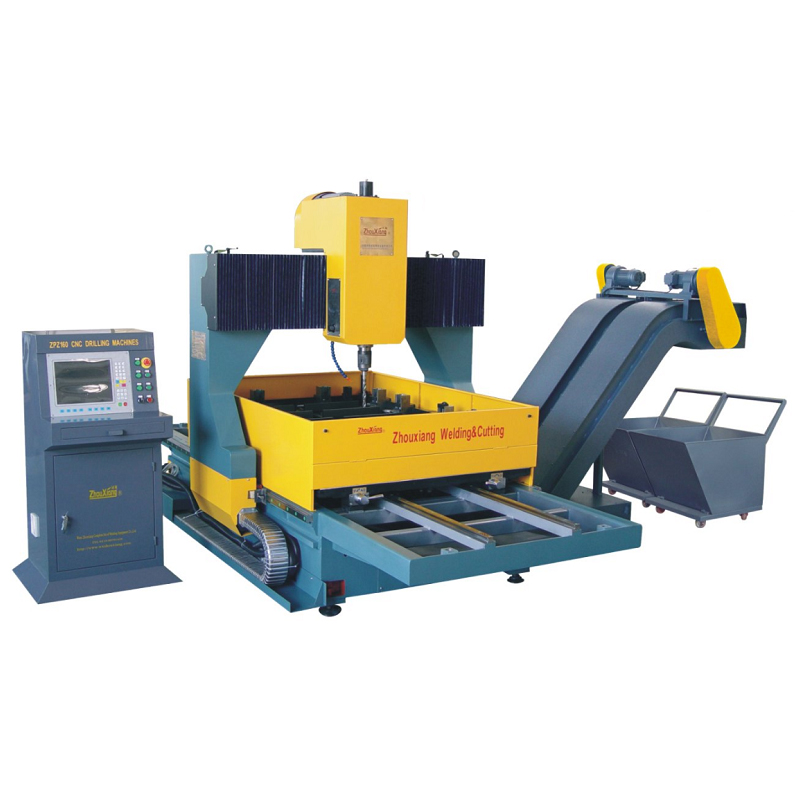

CNC drilling machine

- Product Details

- Company Profile

CNC drilling machine, widely used in steel structure construction, is suitable for the components hole-drilling procedure.

ZPZ series CNC drilling machine, widely used in steel structure construction, is suitable for the components hole-drilling procedure.

If the number of the common contact plate bulk is large, the adoption of the machine can reduce manual labor intensity, improve production efficiency, and guarantee the machining accuracy of the work-piece

High production efficiency: There are two movable worktables. When one table is drilling, the other can handle parts (load or unload) at the same time, so the machine can do non-stop drilling; with four processing point it can load at the same time 1 ~ 4 parts for processing; 12 movable hydraulic clamps were equipped inside the worktables, which can quickly and conveniently load and unload parts; drilling head’s 6m/min rapid positioning; the spindle head adopts 3 different lengths quick-change drill chuck, which can be chosen by the drill length and thickness.

High precision machining: X/Y-axis is driven by AC servo motor ball screw driving system; power head and worktable are moving in a straight line rolling guide.

Powerful control system: a variety of template programs are set in the system, workers only need to call the program for simple editing, saving processing auxiliary time; when the input data is wrong, it will prompt immediately; real-time display processing status, alarm prompt The following are 12 commonly used template graphics.

Safe and reliable: When a workbench is loading and unloading a workpiece, the power head will not move to this area; the CNC system, electrical actuators, and hydraulic components are all imported from famous brands.

Technical parameter

1. The max thickness of the work-piece: 80mm (σb≤235MPa)

2. The max extension of the work-piece: one basic point :2000×1400mm

two basic points :1000×1400mm

four basic points :1000×700mm

3. Max. drilling diameter: 60mm

4. Main shaft feeding way: lead screw

5. Main shaft rotating speed: 130-400r/min (Stepless speed adjust)

6. Max stroke of main shaft: 180mm

7. Work-piece clamping way: hydraulic

8. Oil-cylinder used for clamping work-piece: 12pcs

9. Main shaft motor power: 7.5kw

10. Hydraulic motor power: 4kw

11. X,Y axis moving speed: 6m/min

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier