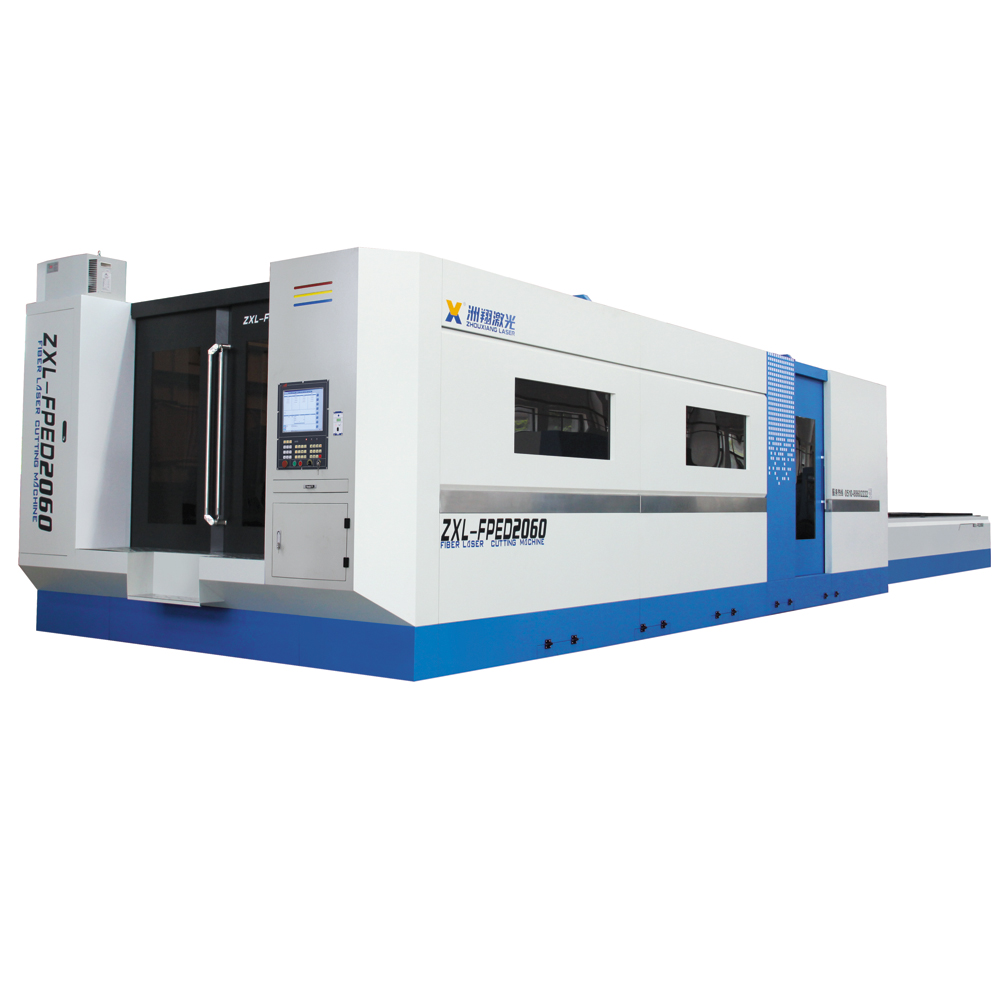

High power fiber laser cutting machine

- Product Details

- Company Profile

Fiber laser cutting machine is the laser cutting machine which use fiber laser producer as light source. Fiber laser is a new type of fiber laser which can output high energy density laser beam, gathered in the workpiece surface, making workpiece instantaneous melting and sublimation by super fine focus flare, which can achieve automatic cutting by moving facula changed by CNC mechanical system. Compared with large-sized gas laser and solid laser, it has become an important candidate of high precision laser machining, laser radar system, space technology, laser medicine, etc. Fiber laser cutting machine not only can do flat surface cutting, but also beveling cutting, with neat, smooth edges, which is very suitable for high precision of cutting processing. Compared to Co2 laser cutting machine, fiber laser cutting machine has high photoelectric conversion rate, it is Energy conservation and environmental protection of the new product, also one of the world's leading technology products.

Laser cutting concentrate the light beam on the material surface by optical focusing mirror, melt the material, blow off the cutting slag by high-speed air flow and form a smooth cutting seam.

Fiber laser cutting machine can be used for plane cutting and also can be used for beveling cutting. The cutting edge is smooth and tidy which is especially for metal plate high accurate cutting, meanwhile the mechanical beam can make three dimensions cutting. Compare with the normal CO2 laser cutting, fiber laser cutting is more costly by saving space and gas consumption, it has high photoelectric converting efficiency as a new product of energy conservation and environment protection, and also one of the world technology leading products. It is widely used in panel beating, aviation, aerospace, electrical equipment, metro parts, automobile, grain machinery, textile machinery, engineering machinery, precise parts, ship, metallurgy machinery, elevator,household appliances, craft gift, tooling processing, decoration, advertisement, metal processing etc. Varies manufacturing and processing industries.

Two exchange working tables, easy operation, and convenient for loading and unloading. This series is suitable for medium thick plate processing.

Technical Parameters

Machine model | FPED2060 |

Laser power | 2000W-12000W |

Cutting thickness | 0.5-30mm |

Working area | 2000 * 6000mm |

Repeat positioning accuracy | ±0.02mm |

Maximum speed | 120m/min |

Max.acceleration | 1.5G |

Voltage and frequency | 380V 50Hz/60Hz |

High Stability Welded table

The internal structure of the table adopts gantry type structure, which is welded by a number of rectangular tubes. Stiffeners are arranged inside the tubes to increase the strength and tensile strength of the table, it also increases the resistance and stability of the guide rail so as to effectively avoid the deformation of the table.

High strength, stability, tensile strength, ensuring 20 years of use without distortion;

Thickness of rectangular pipe wall is 10mm and weights 4500 kg.

High Strength Aluminum Alloy Beam

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier