Electrical appliances mould、mold maker

- Product Details

- Company Profile

Electrical appliances mould、mold maker

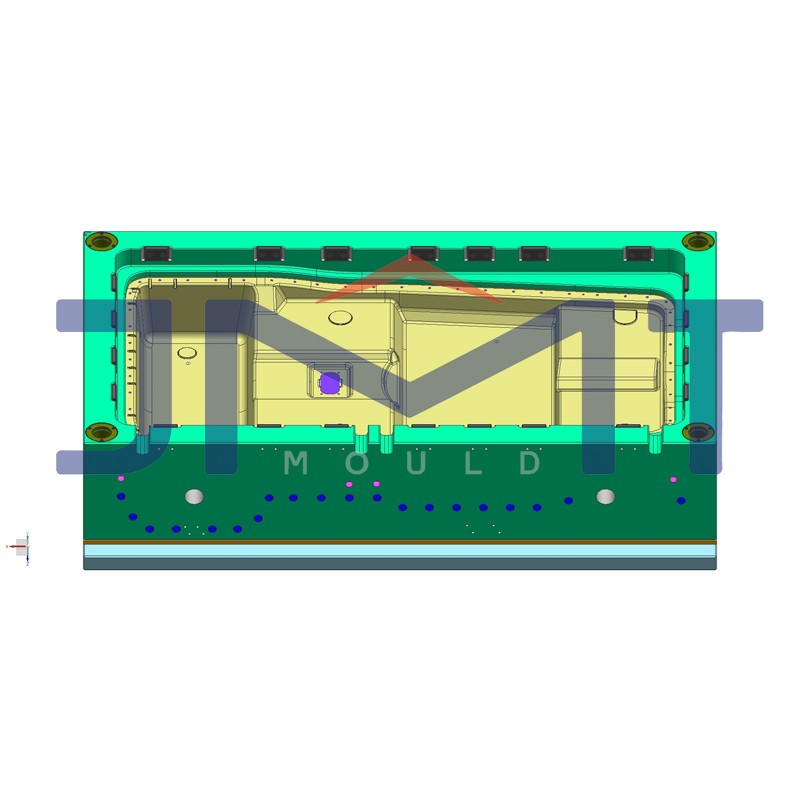

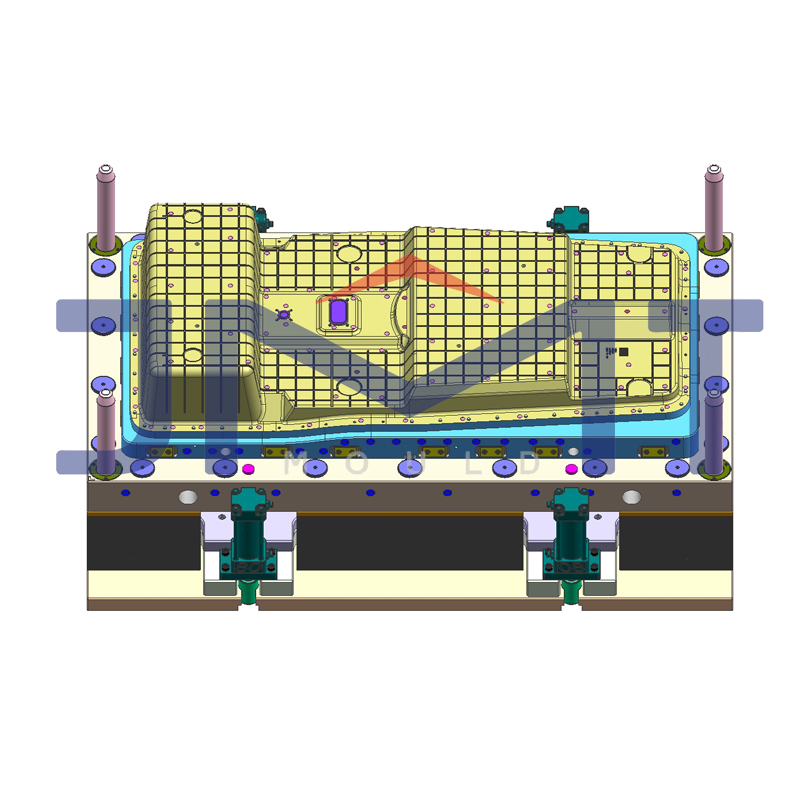

SMC is Sheet molding compound.

SMC is a mixture of polymer resin, inert fillers, fiber reinforcement, catalysts, pigments, stabilizers, release agents, and thickeners. SMC molding is a continuous in-line process.

This process produces high strength, complex parts in a wide variety of sizes. Matched metal dies are mounted in a hydraulic molding press. The material charge is manually or robotically placed in the mold; the heated mold halves are closed, and up to 2,000psi of pressure is applied. Cycle time ranges from one to five minutes, depending on part size and thickness. Features such as ribs, bosses and inserts can be molded in.

Compression molded fiberglass parts are characterized by net size and shape, two excellent finished surfaces, and outstanding part-to-part repeatability. Trimming and finishing costs are minimal.

In-mold coatings and vacuum system in the tool are available to improve surface paint ability, eliminating the need for primer.

Color compounds can be customized.

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier