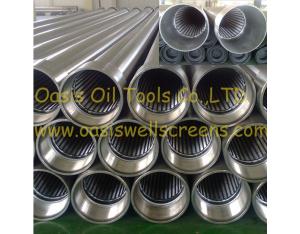

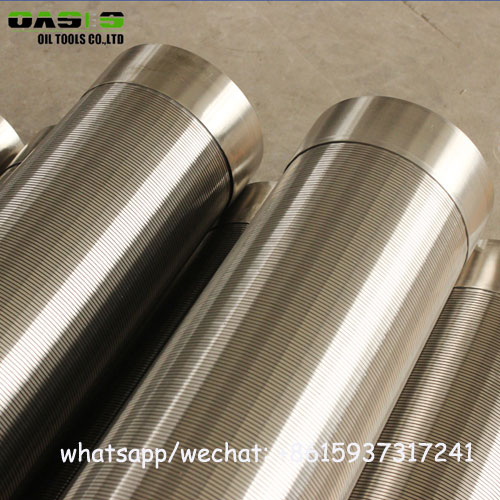

Beveled End Continuous Slot Johnson Wire Wrap Water Well Screens Pipe

- Product Details

- Company Profile

Beveled End Continuous Slot Johnson Wire Wrap Water Well Screens Pipe High Quality Competitive price Timely delivery

Beveled End Continuous Slot Johnson Wire Wrap Water Well Screens Pipe

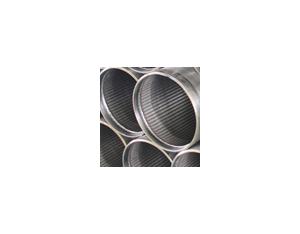

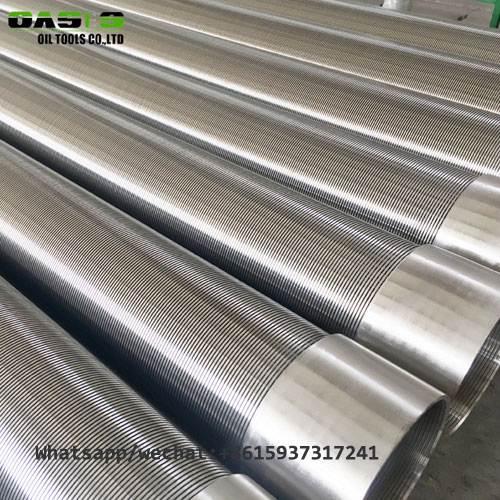

Form: Beveled End Continuous Slot Johnson Wire Wrap Water Well Screens Pipe are manufactured by a v or wedge shaped wire around an internal array of longitudinal support rods. The world advanced all-weld technology is used with each intersecting point of these wire fusion welded, which creates the robust construction and excellent mechanical performance.

Operation principle: The v or wedge shaped profile wire wraps around the support rods over the full length of the screen creating a continuous slot opening, hence the screen allows water to enter the well freely in ample quantities while at the same time keeps the majority of sand and gravel out of the well.

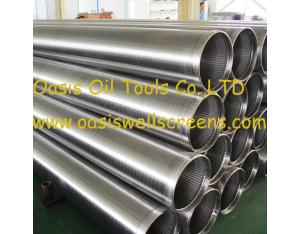

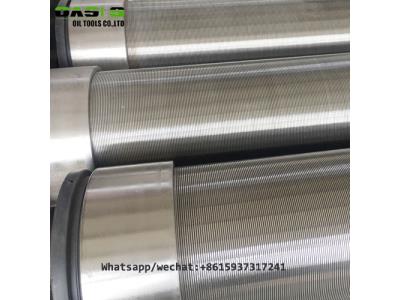

Specifications of Beveled End Continuous Slot Johnson Wire Wrap Water Well Screens Pipe:

1.Material: galvanized carbon steel, stainless steel (304,304L,316,316L etc.)

2.Diameter: 219mm

3.Slot Size (mm): 0.5, or as per customers’ requirement from 0.02mm-3mm

4.Unit length 3m, 6m, 5.8m fit for the 20ft or 40ft container

5.Open area up to 20%

6.End Connection: welding (beveled end), thread coupling(STC,LTC,BTC) or flange

7.Surface treatment:galvanized, painted, polish,etc.

8.Packing: bubble bag and woven bag, in bundle or unbundle or in wooden cases.

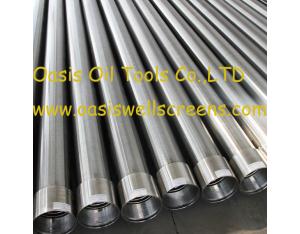

Advantages of Beveled End Continuous Slot Johnson Wire Wrap Water Well Screens Pipe:

1.Better filter function. The V-shape section plane of water well screens(Johnson screens) creates the continuous slot, which can avoid blockage and make sure of the unimpeded water.

2. Prolong life of well. The consecutive slot of water well screens(Johnson screens) have wider open area, and it can reduce the speed of the water entering to avoid the sand entering the screen under the great pressure, so it can control sand better, which can increase the water yield and prolong service time of the well.

3.Long service life. Wire and support rods are all-welded, which makes water well screens(Johnson screens) more robust and longer life.

4.High pressure-resistant. The longitudinal support rods and the continuous slot make the water well screens(Johnson screens) have more excellent pressure-resistant performance.

5.Customized. Specifications and end connections of water well screens(Johnson type screens) can be fabricated according to customers’ requirements.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier