1.8T Wire Splice Band Splicing Machine

- Product Details

- Company Profile

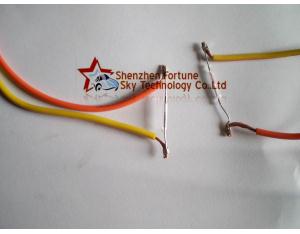

? This 1.8T wire splice band splicing machine is specially designed for wire riveting processing, crimping riveting and wire connection, which replaced the traditional soldering methods to avoid faults of no cold welding, air welding and air pollution.Splice band machine widely admitted to be the most simple and effective way. ? This splice band wire crimping machine uses special continuous copper strip terminal materials to shape molding after being cut off. Pressing quickly at one time without waste and saving cost. ? Splice band is processed by residue lines. Resistance to tension is particularly strong after riveting with stable quality. ? Straight and curved mold bases can be equipped to connect with various products. ? User-friendly design, easy to operate.

This 1.8T is specially designed for wire processing, crimping riveting and wire connection, which replaced the traditional soldering methods to avoid faults of no cold welding, air welding and air pollution.Splice band machine widely admitted to be the most simple and effective way.

This splice band wire crimping machine uses special continuous copper strip terminal materials to shape molding after being cut off. Pressing quickly at one time without waste and saving cost.

Splice band is processed by residue lines. Resistance to tension is particularly strong after riveting with stable quality.

Straight and curved mold bases can be equipped to connect with various products.

User-friendly design, easy to operate.

Description:

Scope of Application:

Neon and resistor connection, LED and wire connections.

Resistor and wire connection.

Slide switch and wire connection.

Connection of high temperature heating elements.

Connection of thermosensitive components (such as magnetic spring, constant temperature fuse).

Transformer tap and wire connection.

Power supply: AC110V/220V 50Hz

Weight: 55 Kg

Dimension (mm): 370x 400×500

Power: 1/4HP

Stroke: 2000KG

Splice Band Size: 2mm/4mm/6mm

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier