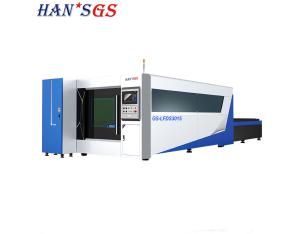

Cheap price laser cutting machine for carbon steel/stainless steel cutting

- Product Details

- Company Profile

Fiber laser cutting machine features: 1. High-rigidity machine tool bed, exclusive high-temperature numerical control electric furnace standard annealing process annealing treatment, can guarantee the long-term stability of the machine tool accuracy; 2. Imported factory-packaged fiber laser with good beam quality, stable performance, no reflection lens, no need to adjust the light path, basic maintenance-free, and the service life can reach more than 100,000 hours 3. Fiber lasers have high electro-optical conversion efficiency and conversion efficiency of up to 30%, which can greatly save power consumption during operation and have extremely low operating costs. 4, using imported guide-driven original and servo motor, high precision, high speed; 5, can easily design a variety of graphics or text instant cutting, simple operation, flexible and convenient. 6. The edge of the cutting edge is smooth, flat and deformed. 7, low energy consumption, energy saving and environmental protection, power consumption is very low, the whole machine power consumption is the same power VAG power of 1/3-1/5, thin plate cutting speed is more than three times YAG; 8, the laser produces no gas, can use air to cut the sheet; 9, cutting speed, operating costs are very low, rapid return on investment

Cheap price laser cutting machine for carbon steel/stainless steel cutting

Fiber laser cutting machine features:

1. High-rigidity machine tool bed, exclusive high-temperature numerical control electric furnace standard annealing process annealing treatment, can guarantee the long-term stability of the machine tool accuracy;

2. Imported factory-packaged fiber laser with good beam quality, stable performance, no reflection lens, no need to adjust the light path, basic maintenance-free, and the service life can reach more than 100,000 hours

3. Fiber lasers have high electro-optical conversion efficiency and conversion efficiency of up to 30%, which can greatly save power consumption during operation and have extremely low operating costs.

4, using imported guide-driven original and servo motor, high precision, high speed;

5, can easily design a variety of graphics or text instant cutting, simple operation, flexible and convenient.

6. The edge of the cutting edge is smooth, flat and deformed.

7, low energy consumption, energy saving and environmental protection, power consumption is very low, the whole machine power consumption is the same power VAG power of 1/3-1/5, thin plate cutting speed is more than three times YAG;

8, the laser produces no gas, can use air to cut the sheet;

9, cutting speed, operating costs are very low, rapid return on investment

Advantage of Fiber Laser Cutting Machine

Compare of different laser sources

| Model of Laser Source | Fiber | CO2 | Disc |

| Electro-opticalConversion Efficiency | 30% | 10% | 15% |

| Max. Output | 50Kw | 20Kw | 8Kw |

| BPP(4/5Kw) | <2.5 | 6 | 8 |

| Life of Diode Pumped | >100,000 | NA. | 10,000 |

| Occupied Area(4/5Kw) | <1M2 | 3M2 | >4M2 |

| Maintenance | no need | need | Often |

| Soft Processing | more suitable | unsuitable | suitable |

| Stability | best | good |

Wuhan Hans Goldensky Laser System Co., Ltd.

Location:Wuhan,Hubei,China

Wuhan Hans Goldensky Laser System Co., Ltd is subsidiary company of Han's Laser Technology Industry Group Co., Ltd, (stock code: 002008). We are high-tech enterprise specialized in R&D, manufacture and sales for complete equipment of high-power laser source, laser cutting, laser welding, laser fusion covering, laser heat-processing and high-speed laser punching machine. We also provide automatic processing solving plans. |

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier