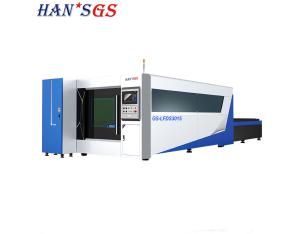

High quality automatic fiber cutting machine stainless steel thick-walled tube thin wall tube laser

- Product Details

- Company Profile

High quality automatic fiber cutting machine stainless steel thick-walled tube thin wall tube laser cutting machine Fiber tube laser cutting machine features 1. The professional control system adopts pipe processing to ensure the processing precision under high-speed movement conditions, with high production efficiency and high processing precision. 2. IPG fiber lasers have low operating and maintenance costs. 3, using open structure, good proximity, convenient loading and unloading operations. With receiving vehicle, so that the receipt more convenient. 4, for high-speed motion requirements, design and manufacture of reinforced welding bed, two effective treatment to ensure the long-term operation of the bed 5,Optimized optical lens, specially designed nozzle and sensor technology make cutting more smooth and more stable.

High quality automatic fiber cutting machine stainless steel thick-walled tube thin wall tube laser cutting machine

Fiber tube laser cutting machine features

1. The professional control system adopts pipe processing to ensure the processing precision under high-speed movement conditions, with high production efficiency and high processing precision.

2. IPG fiber lasers have low operating and maintenance costs.

3, using open structure, good proximity, convenient loading and unloading operations. With receiving vehicle, so that the receipt more convenient.

4, for high-speed motion requirements, design and manufacture of reinforced welding bed, two effective treatment to ensure the long-term operation of the bed

5,Optimized optical lens, specially designed nozzle and sensor technology make cutting more smooth and more stable.

Specifications

| Model | GS-LFTP3015/4015/6015 |

| Output power of laser source (Optional) | 500W/1000W/1500W |

Cutting area (L * W) (Optional) | 3000 * 1500 mm 4000 * 1500 mm 6000 * 1500 mm |

| Max. tube diameter | 200 mm |

| Max. tube processing length | 3 m |

| Max. tube cutting thickness | 6 mm |

| X axle stroke | 3048 mm |

| Y axle stroke | 2000 mm |

| Z axle stroke | 80 mm |

| Cooling | water cooling |

| Max. accelerated speed of X, Y axles | 1.2 G |

| Kerf Width | 0.1 - 0.3 mm |

| Positioning accuracy of X, Y and Z axles | ± 0.05 mm |

| Repeated positioning accuracy of X, Y and Z axles | ± 0.03 mm |

| Processing precision of work piece | ± 0.1 mm |

| Kerf harshness | Ra 3.2 - 12.5 μm |

| Voltage | 380V, 50/60Hz |

| Continuous working time | 24 Hours |

| Max. bearing weight of working platform | 600 Kgs |

| Total installed capacity | 20 - 25 KVA |

| Total protection level of power supply | IP54 |

Laser Indication system

The fiber laser cutter equip with laser indication system(red light indication) to help operator to verify the position on the cutting board of the cutting head. Semi-conductor red wavelength (638nm).

Dust pelletizing system

The fiber laser cutting machine equips with big air blow fan to remove the dust, exhaust during the work, and will discharge after filtration

Packing

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier