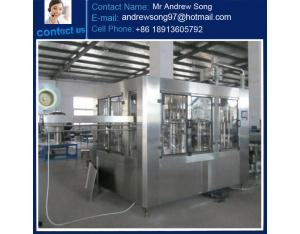

Best Price Automatic Water Filling 3 In 1 Unit (Washing Filling Capping)

- Product Details

- Company Profile

The machine deals with mineral water filling and pure water filling, with rinsing and capping in one machine. The machine integrates rinsing, filling and capping in monobloc machine.

Best Price Automatic Water Filling 3 In 1 Unit (Washing Filling Capping)

The machine deals with mineral water filling and pure water filling, with rinsing and capping in one machine. The machine integrates rinsing, filling and capping in monobloc machine.

1. capacity: 8000-10000b/h @500ml

2. fixed liquid level pressure filling, avoiding leakage.

3. spring type rinsing clamp, rinsing empty bottle both outside and inside.

4. magnetic torque type cap screwer.

5. PLC control and touch screen.

Bottle Washing: The bottles are first picked up using an automatic robot arm, which tilts the bottle on top of a rinsing spray, which rinses the bottles in three stages. The bottles are cleaned with clean water.

Bottle Filling: After rinsing the bottles are transferred by neck to the filling station. Here the bottles are filled accurately by filling valves. The filling valves are very accurate and give equal filling to every bottle.

The special feature in the system is that no bottle no wash and no bottle no fill.

Bottle Capping: After filling, bottles automatically move for the capping stage where the caps are released from the vibrator on the bottle. The caps are sealed automatically using screw capping heads.

Bottled Filling and Sealing Machine's Main Technical Parameter

| Model | CGF16-12-6 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 | |

| Production Capacity | 2000-4000 | 4000-6000 | 8000-10000 | 12000-15000(0.5L) | |

| Filling Precision | <=5mm(Liquid level) | ||||

| Polyester Bottle Standard(mm) | Bottle Diameteφ40-φ80 | Bottle Diameter φ50-φ100 Height 150-320 | |||

| Suitable Cap Shape | Plastic Screw Cap | ||||

| Water Pressure of Washing Bottle(Mpa) | 0.18 | ||||

| Water Consumption for Water Bottle(kg/h) | 800 | 1600 | 2500 | 3500 | |

| Spraying Position | 5 | 5 | 6 | 12 | |

| Dripping Bottle Position | 3 | 3 | 3.5 | 7 | |

| Gas Source Pressure | Normal | ||||

| Gas Consumption(m³/min) | 0.3 | 0.3 | 0.4 | 0.5 | |

| Total Power(kw) | 5.03 | 5.03 | 6.57 | 8.63 | |

| Total Weight(kg) | 2000 | 3500 | 5500 | 8000 | |

| Dimension(L*W*H)(mm) | 2100*1500*2200 | 2450*1800*2200 | 2750*2180*2200 |

Zhangjiagang Baixiong Machinery CO.,LTD.

Location:Suzhou,Jiangsu,China

| |

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier