Automatic Bottle carbonated drink Machine Zhangjiagang

- Product Details

- Company Profile

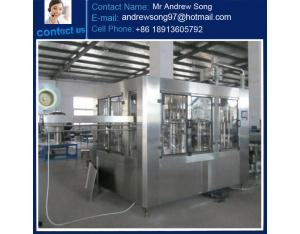

This filler is developed on the basis of digesting and absorbing advanced technology introducing from abroad and is with international advanced level. It is mainly used for filling gas-containing drink, such as aerated water, cola sparking wine, fruit tea soda water and so on. It is advanced in construction, steadily in performance, safe in operation, easy in maintenance high in production efficiency, and the speed can be regulated infinitively. This equipment is the ideal choice for drink factories of soda water drinks.

Automatic Bottle carbonated drink Machine Zhangjiagang

1.Automatic Bottle carbonated drink Machine Zhangjiagang is economic choice for medium capacity needed but less invested soft drink plant.

2. There are three machines separately existence of this carbonated drinks production line.

3. First is bottle washer, when the bottles coming along by the automatic conveyor, the bottles will be washed inside one by one with the pure water.

4. Second is the carbonated drinks filling machine, as the washed bottled conveyed to this machine, the filling part start filling, bottles stand around under the filling valve. Then the drinks filling into the bottles .

5. Third is the bottle capper machine, after finish filling from the soda water filling machine, the bottles conveyed by the conveyor to the capper machine. The capper will be capped on the bottle neck, then the bottled drinks finished.

This filler is developed on the basis of digesting and absorbing advanced technology introducing from abroad and is with international advanced level. It is mainly used for filling gas-containing drink, such as aerated water, cola sparking wine, fruit tea soda water and so on. It is advanced in construction, steadily in performance, safe in operation, easy in maintenance high in production efficiency, and the speed can be regulated infinitively. This equipment is the ideal choice for drink factories of soda water drinks.

Main technological data:

| Model : | DG -8 | DG -12 | DG-18 | DG -24 | DG -32 |

| Production Capacity: | 1000-2000b/h | 1000-3000b/h | 2500-4600b/h | 2500-6000b/h | 3000-8000b/h |

| Bottle /standard: | Glass bottle , PVC bottle , Pop-top can | ||||

| Filling Pressure: | 0.2-0.3Mpa | ||||

| Filling Temperature: | 2-6 | ||||

| Power: | 0.75kw | 1.1kw | 1.5kw | 1.5kw | 2.2kw |

| Overall Dimensions: | 1000×900×1800 mm | 1100×1050×1800 mm | 1400×1300×1800 mm | 1600×1540×1800 mm | 1900×1500×2000 mm |

| Weight : | 1000kg | 1600kg | 2100kg | 2700kg | 3500kg |

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier