Automatic carbonated soft drink bottling filling processing machine

- Product Details

- Company Profile

soft drink bottling process is used to fill carbonated drink and soft drink into plastic bottles, glass bottles, aluminum can etc. For example, sprite, cola, flavored juice with carbon dioxide. The processing of the soft drink includes: syrup melting - flavored mixing - filteration - carbon dioxide mixer - filling machine - packing machine - PET bottle making machine. All the processing is customize basing on the different production capacity per hour, filling liquid, bottle types and caps. Different liquid, bottle and cap are different, the filling valve, filling nozzle, bottle carry system are totally different.

Automatic carbonated soft drink bottling filling processing machine

Product Application

soft drink bottling process is used to fill carbonated drink and soft drink into plastic bottles, glass bottles, aluminum can etc. For example, sprite, cola, flavored juice with carbon dioxide.

The processing of the soft drink includes: syrup melting - flavored mixing - filteration - carbon dioxide mixer - filling machine - packing machine - PET bottle making machine.

All the processing is customize basing on the different production capacity per hour, filling liquid, bottle types and caps. Different liquid, bottle and cap are different, the filling valve, filling nozzle, bottle carry system are totally different.

The complete solution of soft drink production line, including:

1, Water treatment system

2, Soft drink processing machine

3, Soft drink filling machine

4, Bottled soft drink packing machine

5, PET bottle blow molding machine

6, Bottle unscrambler

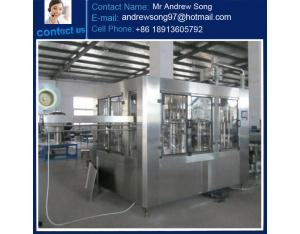

The photo below is taken by YuFeng Beverage Machinery:

Bottle type:250ml-500ml-750ml-1000ml-1500ml PET bottle

Cap type: normal plastic screw cap

Production capacity: 10000-12000 bottles per hour for 500ml bottle

Filling liquid: carbonated drink, soft drink, soda and another liquid with carbon dioxide

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier