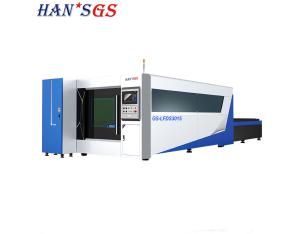

1500W sheet metal processing entry platform metal sheet metal laser cutting equipment

- Product Details

- Company Profile

Product description 1, the choice of Germany IPG fiber laser, high photoelectric conversion efficiency, stable performance, the life of key components up to 100,000 hours. 2, Standard 500W fiber laser, optional 300W-1000W fiber laser. Fiber lasers have high beam quality, high slew rates, and very low operating and maintenance costs. 3, the laser generation process does not require gas, air-assisted cutting, optical transmission, without adjusting the optical path, easy to operate, the cost is very low. 4, compared with other media laser equipment, fiber optic focus spot smaller, so that cutting fine lines, higher efficiency, better processing quality; 5, with the company independently design gantry CNC machine tools using dual-drive system, the use of high-strength overall welded fuselage, after high temperature annealing, deformation does not occur, to protect the long-term high-speed cutting smoothness. 6, with good rigidity, stability, precision ball screw, linear guide drive operation. 7, equipped with high-precision, high response drive, suitable for the following 5mm fast metal plate cutting. Functions of GS-LFD2513 laser cutter 1. Equipped with exhaust device, have good exhausting effect and little pollution. 2. Small occupied area, high system integration, convenient to operate and maintenance,24 hours continuous working. 3. The water chiller has good safety protection function, such as over temperature, lack phase, pressure, water-break, undervoltage, overload, etc. With stable performance, satisfied the cooling requirement of laser source.

1500 Watt sheet metal processing entry platform metal sheet metal cutting equipment cutting machine

Product description

1, the choice of Germany IPG fiber laser, high photoelectric conversion efficiency, stable performance, the life of key components up to 100,000 hours.

2, Standard 500W fiber laser, optional 300W-1000W fiber laser. Fiber lasers have high beam quality, high slew rates, and very low operating and maintenance costs.

3, the laser generation process does not require gas, air-assisted cutting, optical transmission, without adjusting the optical path, easy to operate, the cost is very low.

4, compared with other media laser equipment, fiber optic focus spot smaller, so that cutting fine lines, higher efficiency, better processing quality;

5, with the company independently design gantry CNC machine tools using dual-drive system, the use of high-strength overall welded fuselage, after high temperature annealing, deformation does not occur, to protect the long-term high-speed cutting smoothness.

6, with good rigidity, stability, precision ball screw, linear guide drive operation.

7, equipped with high-precision, high response drive, suitable for the following 5mm fast metal plate cutting.

Parameters

| Model | GS-LFD2513 |

| Laser source medium | Fiber |

| Laser power | 500W/1000W/1500W |

| Cutting range(L*W) | 2500mm × 1300mm |

| Z axle stroke | 100 mm |

| Max positioning speed | 120m/min |

| Max height of feeding material | more than 120mm |

| Cooling form | water cooling |

| Laser wavelength | 1070nm |

| Min. cutting gap | ≤0.1mm |

| Positioning accuracy of X, Y and Z axles | ±0.03 mm |

| Repeated positioning accuracy of X, Y and Z axles | ±0.01 mm |

| Drive model | Imported servo motor |

| Power requirement | 380V,50/60Hz |

| Working temperature | 5℃-45℃ |

| Continuous working time | 24 Hours |

| Outer dimension | 4270mm x2280mm x 1750mm |

Wuhan Hans Goldensky Laser System Co., Ltd.

Location:Wuhan,Hubei,China

Wuhan Hans Goldensky Laser System Co., Ltd is subsidiary company of Han's Laser Technology Industry Group Co., Ltd, (stock code: 002008). We are high-tech enterprise specialized in R&D, manufacture and sales for complete equipment of high-power laser source, laser cutting, laser welding, laser fusion covering, laser heat-processing and high-speed laser punching machine. We also provide automatic processing solving plans. |

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier