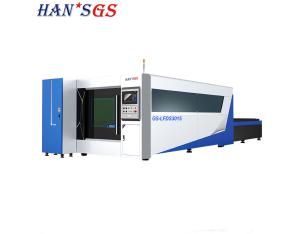

1000w Stainless Carbon Steel Fiber Laser Cutting Machine for Galvanized Plate

- Product Details

- Company Profile

Product description GS-LFDS high-speed dual-drive interactive laser cutting machine is a KARASKAI laser a reached the international advanced level of mature products. The product possesses unparalleled advantages such as great cutting ability, outstanding cutting speed, extremely low running cost, excellent stability, high quality cutting quality and strong adaptability. GS-LFDS high-speed dual-drive interactive laser cutting machine is composed of laser, control system, motion system, optical system, cooling system, exhaust system and blow protection system, etc., using the most advanced control mode to achieve multi-axis linkage and with Speed power regulation, superior performance of servo motor and drive-oriented structure to achieve high-speed state has good motion accuracy. Advantages of Fiber laser cutting machine: 1. Low cost: 30% photo-electric conversion efficiency, low power consumption. 2. Free maintenance: without reflective lenses, no need to adjust laser route. 3. High speed: with IPG/ROFIN laser source, hing speed running. 4. High cutting quality: less deformation, flat and elegant surface. 5. High precision: Adopt high precision drive structure with imported service motor, ±0.03mm positioning precision. 6. Strong software: any shape, easy and convenient operation. 7. Compacted structure, small occupied area. 8. Environmental protection, longer lifetime. 9. With safety sheild, ensure the safety of machine and operators.

Product description

GS-LFDS high-speed dual-drive interactive laser cutting machine is a KARASKAI laser a reached the international advanced level of mature products. The product possesses unparalleled advantages such as great cutting ability, outstanding cutting speed, extremely low running cost, excellent stability, high quality cutting quality and strong adaptability.

GS-LFDS high-speed dual-drive interactive laser cutting machine is composed of laser, control system, motion system, optical system, cooling system, exhaust system and blow protection system, etc., using the most advanced control mode to achieve multi-axis linkage and with Speed power regulation, superior performance of servo motor and drive-oriented structure to achieve high-speed state has good motion accuracy.

Used in sheet metal processing, aviation, electronics, electrical appliances, subway accessories, automotive, food machinery, textile machinery, construction machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, kitchen utensils, craft gifts, tools, decoration, advertising , Metal processing and other foreign licensed processing industry.

Used in sheet metal processing, aviation, electronics, electrical appliances, subway accessories, automotive, food machinery, textile machinery, construction machinery, precision parts, ships, metallurgical equipment, elevators, household appliances, kitchen utensils, craft gifts, tools, decoration, advertising , Metal processing and other foreign licensed processing industry.

Technical Parameter

| Model | GS-LFDS3015 | ||

| Power of laser source | 1000W | 1500W | 2000W |

| Cutting area (L*W) | 3000x1500mm | ||

| Z axle height | 150mm | ||

| Max. cutting speed | 36m/min | 40m/min | 45m/min |

| Max. Cutting thickness (according to the materials) | 0.1-8mm | 0.1-12mm | 0.1-16mm |

| Max. positioning speed | 120m/min | ||

| Max height of feeding material | Less than 120mm | ||

| Occupied area | 7400 mm × 2860 mm × 2000mm | ||

| Cooling | water cooling | ||

| Laser wavelength | 1070nm | ||

| Min. cutting gap | ≤0.1mm | ≤0.125mm | ≤0.125mm |

| Positioning accuracy | ±0.03 mm | ||

| Re-positioning accuracy | ±0.02 mm | ||

| Drive model |

Wuhan Hans Goldensky Laser System Co., Ltd.

Location:Wuhan,Hubei,China

Wuhan Hans Goldensky Laser System Co., Ltd is subsidiary company of Han's Laser Technology Industry Group Co., Ltd, (stock code: 002008). We are high-tech enterprise specialized in R&D, manufacture and sales for complete equipment of high-power laser source, laser cutting, laser welding, laser fusion covering, laser heat-processing and high-speed laser punching machine. We also provide automatic processing solving plans. | ||

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier