cnc metal cutting laser cutter machine for 3mm 6mm 12mm 16mm steel plate cutting

- Product Details

- Company Profile

Product Introduction laser cutting machine is a complete set of laser cutting machine with optical, mechanical and electrical integration. The equipment consists of fiber laser, chiller, fiber cutting head, cutting machine, exchange table, control system, And ventilation systems and other functional components integration. Advantages: 1. Smaller Focal spot and cutting gap. Much more efficient and better processing quality. 2.Extremely high cutting speed which equals to two times of tradition CO2 laser cutting machine with same power specification. 3.Adopt international top brand laser source with stable performance. 4.The photoelectric conversion rate is three times higher than traditional CO2 laser cutting machine, and it's environmental protection. 5.Lower running cost compared with traditional CO2 laser cutting machine, the power consumption is 20%-30% of CO2 laser cutting machine. 6.The maintenance cost of fiber laser cutting machine is much lower since it's without reflective lenses. 7.Convenient operation with fiber transmission, laser route adjustment is unnecessary. 8.Satisfied with flexible processing with small size and intense structure design.

Parameters

| Model | GS-LFDS3015 |

| Laser source medium | Fiber |

| Cutting range (L * W) | 3000 mm × 1500 mm |

| Z axle stroke | 250 mm |

| Max. positioning speed | 120 m/min |

| X,Y axle Max. accelerate speed | 1.2G |

| Cooling form | Water cooling |

| Laser wavelength | 1070nm |

Output power of laser source | 1000W / 1500W / 2000W 2500W / 3000W / 4000W (Optional) |

| Min. cutting gap | ≤ 0.1 mm |

| Positioning accuracy of X, Y and Z axles | ± 0.03 mm |

| Repeated positioning accuracy of X, Y and Z axles | ± 0.01 mm |

| Thickness of cutting material (according to material) | 0.2 - 25 mm |

| Drive model | Imported servo motor |

| Power requirement | 380V, 50/60 Hz |

| Working temperature | 5-45℃ |

| Continuous working time | 24 Hours |

| Machine weight | About 12130 Kgs |

| Total protection level of power supply | IP54 |

1. Smaller Focal spot and cutting gap. Much more efficient and better processing quality.

2.Extremely high cutting speed which equals to two times of tradition CO2 laser cutting machine with same power specification.

3.Adopt international top brand laser source with stable performance.

4.The photoelectric conversion rate is three times higher than traditional CO2 laser cutting machine, and it's environmental protection.

5.Lower running cost compared with traditional CO2 laser cutting machine, the power consumption is 20%-30% of CO2 laser cutting machine.

6.The maintenance cost of fiber laser cutting machine is much lower since it's without reflective lenses.

7.Convenient operation with fiber transmission, laser route adjustment is unnecessary.

8.Satisfied with flexible processing with small size and intense structure design.

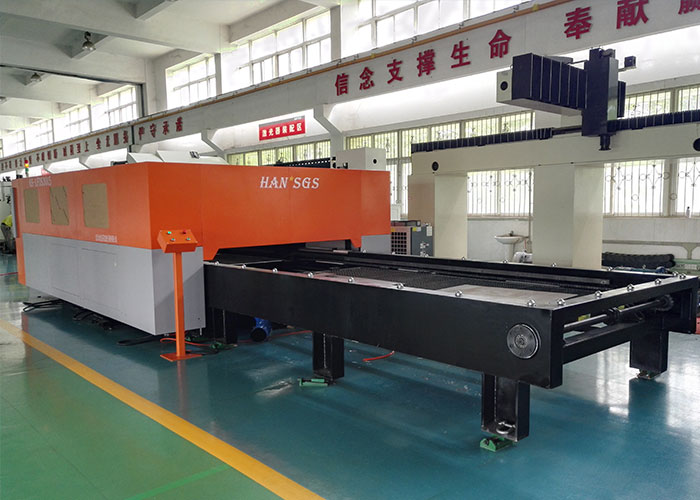

Customer site

Cutting Sample

Packing & Shipping

Our company

Core enterprise of Optic Valley in Wuhan

Founded in 1998, registered capital 80 million, total asset 0.13 billion

20000m2 Industry Park

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier