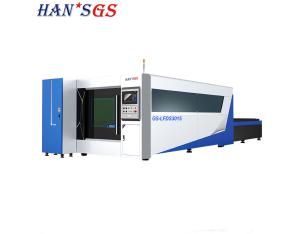

1500W 2000W stainless steel mild steel Aluminum hot sale metal CNC fiber laser cutting machine

- Product Details

- Company Profile

Fiber laser cutting machine It can do plane cutting, but also do bevel cutting, and the edge neat, smooth, suitable for high precision metal plate cutting, at the same time with the arm can be three-dimensional cutting instead of the original five Axis laser. Compared with ordinary carbon dioxide laser cutting machine to save space and gas consumption, high photoelectric conversion rate, is a new energy-saving products, but also one of the world's leading technology products. Fiber Laser Cutting Machine Advantages Cutting knife is narrow and parallel on both sides, also perpendicular to surface, dimensional accuracy of cutting pieces can be up to + / - 0.05 mm. Cutting surface is smooth and beautiful, the surface roughness is only a few dozen microns, laser cutting can be used as the final working procedure, parts can be even used directly without mechanical processing. Heat affected zone is very small, material performance is hardly affected near the kerf width , and the workpiece deformation is small. Also, kerf geometry is good , slitting rectangular cross-section shapes appear to be regular.

Product Description

Fiber laser cutting machine It can do plane cutting, but also do bevel cutting, and the edge neat, smooth, suitable for high precision metal plate cutting, at the same time with the arm can be three-dimensional cutting instead of the original five Axis laser. Compared with ordinary carbon dioxide laser cutting machine to save space and gas consumption, high photoelectric conversion rate, is a new energy-saving products, but also one of the world's leading technology products.

Laser Source Power/Cutting ability

| Laser Source Power/Cutting ability | CS(mm) | SS(mm) | Alumium(mm) | Brass(mm) | |

| 500W | Max cutting thickness | 8 | 4 | 2 | 2 |

| Max processing thickness | 5 | 3 | |||

| 700W | Max cutting thickness | 10 | 6 | 3 | 3 |

| Max processing thickness | 6 | 5 | |||

| 1000W | Max cutting thickness | 14 | 8 | 4 | 4 |

| Max processing thickness | 8 | 6 | |||

| 1500W | Max cutting thickness | 16 | 10 | 6 | 5 |

| Max processing thickness | 12 | 8 | |||

| 2000W | Max cutting thickness | 20 | 12 | 8 | 6 |

| Max processing thickness | 16 | 10 | |||

| 2500W | Max cutting thickness | 22 | 12 | 10 | 8 |

| Max processing thickness | 20 | 10 | |||

| 3000W | Max cutting thickness | 25 | 14 | 12 | 8 |

| Max processing thickness | 22 | 12 | |||

GS-LFDS3015 Technical Specifications

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier