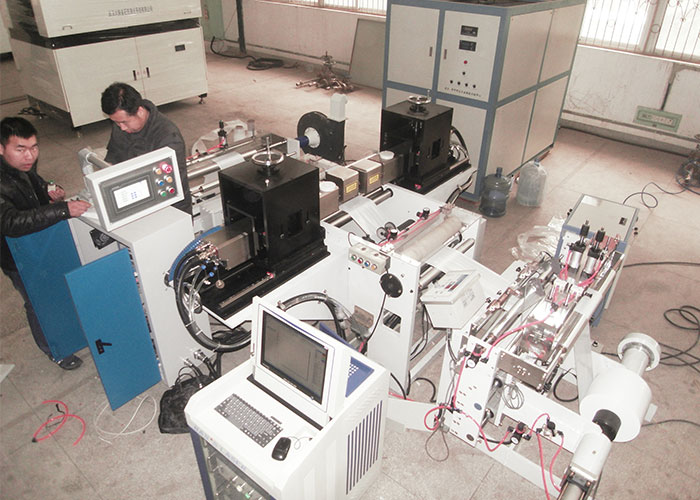

GS-DKJ02 plastic film laser perforating complete sets of equipment

- Product Details

- Company Profile

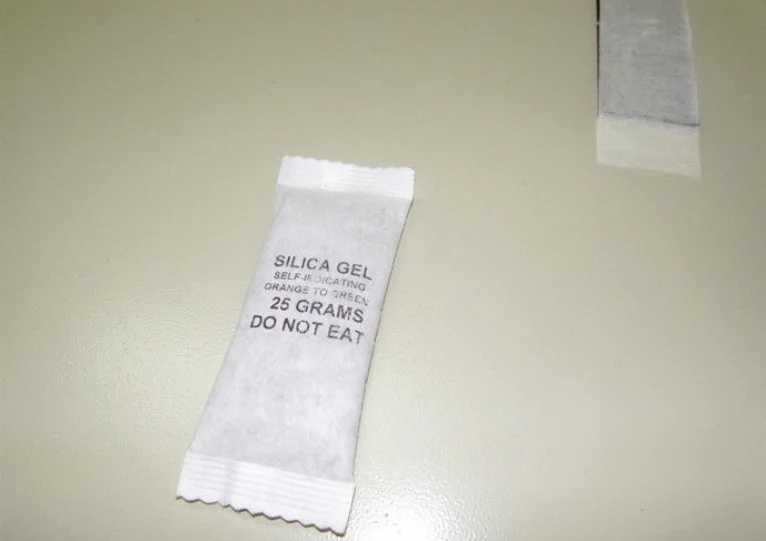

Description: Laser microporous processing is to make a series of small holes on the packaging materials which can easily tear and adjust the moisture inside the packaging. Laser microporous processing can make thick, sturdy packaging material open easily while maintaining the structural strength. Laser microporous processing can also be used in all kinds of packaging products, to control the airflow and moisture release to keep fresh. Wide prospect of the technology which can increase fresh products shelf time, or just release the air inside the packaging. Usually, the advantage of laser mictoporous punching is that the focus laser spot evaporate the holes on materials directly, not mechanical punching to pierce or tear materials. Therefore, the laser microporous punching is more evenly than other punching machining methods . Advantages: 1.Wide range of materials can be processed 2.Clean micro-perforation holes - Heat energy seals the edge of the holes making them stronger. No slugs remain on the film. 3.Enhanced shelf life -Micro-perforations help achieve airflow and moisture release to maintain freshness of produce. 4.Easier filling / no spillage - Air is removed quickly during filling. Micro-perforations allow air to escape while containing product. Packages are more compressed and stack better. 5.Reduced shipping costs - More packages compress to fit a container. Shipping load is more stable.

GS-DKJ02 plastic film laser perforating complete sets of equipment

Competitive Advantage:

Laser Source

Using US brand Coherent laser generator, the laser wave length is 10.6 μm, which belongs to infrared channel. CO2 laser generator has big power and high Electro optic conversion rate, it’s mature and widely used laser generator. CO2 laser source use CO2 gas as working medium, filling CO2 and other auxiliary gas into the discharging tube. The glow discharge will occur in the tube when there’s high voltage electricity affected on the electrode so that the gas molecule release the laser. The laser beam after expansion can be used for laser processing.

Two dimension adjustment table

The two dimension adjustment table is used for the adjustment for the vertical and horizontal position of the laser source. The horizontal adjustment is for the perforating edge distance. The vertical adjustment is for the focus distance. Adjustment for row space of double or three rows is realized within the interior of the focus head.

Specification:

| Model | GS-DKJ02 |

| realize ventilation | 55W, 100W 200W |

| Hole diameter | Ø0.1-Ø0.2m |

| Hole length: plastic wrap length | plastic wrap length |

| Row space adjustment range | 0-20mm |

| Speed | 0-200m/min |

| Hole space adjustment range | 1-10mm |

| Row | 4 (can be set) |

| Area: | 150-550mm |

| Horizontal adjustment travel of the shock focus | 300mm |

| Vertical adjustment range | 50mm |

| Perforating range | 60mm x 60mm |

Note : Single layer perforating, Bottom layer without hole can be realized during the double layer plastic.

Machine parts

Advantages:

1.Wide range of materials can be processed

2.Clean micro-perforation holes - Heat energy seals the edge of the holes making them stronger. No slugs remain on the film.

3.Enhanced shelf life -Micro-perforations help achieve airflow and moisture release to maintain freshness of produce.

4.Easier filling / no spillage - Air is removed quickly during filling. Micro-perforations allow air to escape while containing product. Packages are more compressed and stack better.

5.Reduced shipping costs - More packages compress to fit a container. Shipping load is more stable.

Application:

Fresh-keeping packaging (MAP), the new harvest of agricultural products, sliced fruits, vegetables, salty snacks, sliced meat, half baked food, frozen food, microwave food, pet food, bird food, fertilizer, cement, grass seed, salt/melting ice.

.jpg)

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier