HANS GS laser welding supplier Supply wuhan gear ring seam automatic laser welding machine

- Product Details

- Company Profile

Welding machine features 1.Set four station tray, respectively, feeding, to be processed, welding and cutting station 2.Configure specific carriages to facilitate product specification changes and automated operations 3.Set anti-spatter plate to prevent tooth surface damage 4.Set the pressure plate, rotating together with the workpiece to reduce the laser welding deformation 5.Two-dimensional loading and unloading device and the four-station tray combination, to complete the automated production 6.Preheating device and conveyor integrated design 7.The second station to complete the welding machine gear shaft 8.Segmented welding detection device automatically determine the starting point of welding 9.Weld infrared temperature detection device 10.Machine automatic and manual welding easy to switch

Welding method

Adjust the laser output head is facing the weld of the workpiece, the laser welding head to maintain continuous laser output, the workpiece by the electric rotary translation stage driven uniform operation for a week to complete the welding.

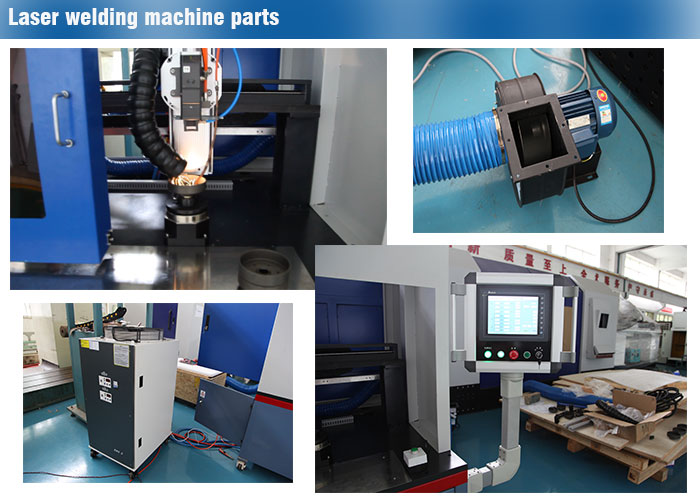

Welding host

There are several main components: rack, electric translation stage, electric rotary table, manual angular displacement stage, laser welding head, electrical control section. The Z-axis is used to adjust the welding focal length. The X-axis can adjust the welding point according to the clutch size. The angular displacement stage can adjust the pitch angle of the workpiece according to the welding process. The C-axis is used to drive the workpiece to rotate one week during welding.

Performance

| Host | GS-HZ03 |

| Laser generator | IPG1000W |

| Control System | PLC |

| Servo motor and drive | X-axis: 400KW; stroke 150mm Z axis: 400W with brake; stroke 300mm C axis: 400KW; 360 degree rotation |

| Precision linear guide, screw | HIWIN |

| Temperature and humidity control machine | 250W |

| cooling system | HC050M |

| Lubrication system | Axis lubrication |

| Maximum welding diameter | Φ200 mm |

| Equipment area | 2m x 2.5m |

Laser welding machine parts

Our Company

WUHAN HANS GOLDENSKY LASER SYSTEM CO., LTD. was established in 1998 as a subsidiary of Han's Laser and is located in "China Optics Valley" of East Lake Technology Development Zone in Wuhan. It is mainly engaged in the R & D, production and sales of high-power laser processing complete sets of equipment, Technology companies.

Product

WUHAN HANS GOLDENSKY LASER SYSTEM CO., LTD.is a high-power laser processing solutions provider. Leading products include: laser cutting complete sets of equipment, laser heat treatment / cladding complete sets of equipment, laser welding complete sets of equipment, laser drilling complete sets of equipment, such as more than 40 different types of laser processing equipment and ancillary products. These products are more independent intellectual property rights, widely used in iron and steel metallurgy, petroleum, metal processing, tobacco and paper processing, hardware tools, automotive, machinery, aerospace, chemical, electronics manufacturing and other industries, these industries have overcome a number of Technical problems, won the laser heat treatment / cladding equipment, high-power gear laser welding equipment, cigarette paper and other parts of the laser drilling equipment market share in the first domestic share.

Technical conditions

The company has undertaken thirty government awards at all levels of government science and technology projects and scientific and technological achievements, was included in the Wuhan City Eleventh Five-Year Plan "large-scale laser equipment systems integration and new laser manufacturing," key support and guide enterprises.

The company is a leader in high-power laser industry in China and possesses key core technologies and advanced international unit technologies in high-power laser welding. The product has strong ability of continuous innovation and is the key to the development of laser processing.

Companies in steel, petrochemical, automotive and many other industries for many years, has accumulated rich experience in laser processing system integration and laser processing technology.

Sample

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier