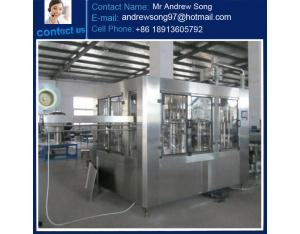

5 gallon barrel water filling machine

- Product Details

- Company Profile

This 5 gallon barrel water filling machine is suitable to produce barrel water,wine, vinegar, medicine and so on. This series filling production line integrates washer, filler and sealer into one unit. In order to achieve the purpose of washing and sterilizing, bottle washer adopts multiple liquid injections washing and disinfectant spray, and washing solution can be used circularly. The sealer can seal bottle caps automatically. This line equips with water spraying device to sterilize caps of bottles in order to ensure those caps are aseptic and healthy, also this line can automatically carry out bottle feeding washing, sterilizing, filling capping, counting and products discharging. It has complete functional, novel design, and high degree of automation. It is a new kind of barreled water auto-producing line, which integrates mechanism, electricity and pneumatics technologies together.So it has full functions, low energy consumption, low investment,and higher and fast effecting characteristic.

5 gallon barrel water filling machine

Further Characteristics

1.Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan\'s Mitsubishi, France Schneider, OMRON.

| Model | QGF100 | QGF300 | QGF450 | QGF600 | QGF900 |

| Filling Volume | 18.9L | 18.9L | 18.9L | 18.9L | 18.9L |

| Bottle Specification | 270*490mm | 270*490mm | 270*490mm | 270*490mm | 270*490mm |

| Capacity(BPH) | 100 | 300 | 450 | 600 | 900 |

| Air pressure(Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Air consumption | 300L/min | 400L/min | 500L/min | 500L/min | 800L/min |

| Power(KW) | 2.12 | 6.5 | 7.5 | 7.5 | 10 |

| Rated voltage(V) | 380 | 380 | 380 | 380 | 380 |

| Dimensions(L*W*H) | 3850*700*1550 | 5130*2500*2220 | 6600*3500*2170 | 6600*3500*2170 | 6600*5000*2170 |

.jpg)

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier