Slip On Wire Wrap Screen

- Product Details

- Company Profile

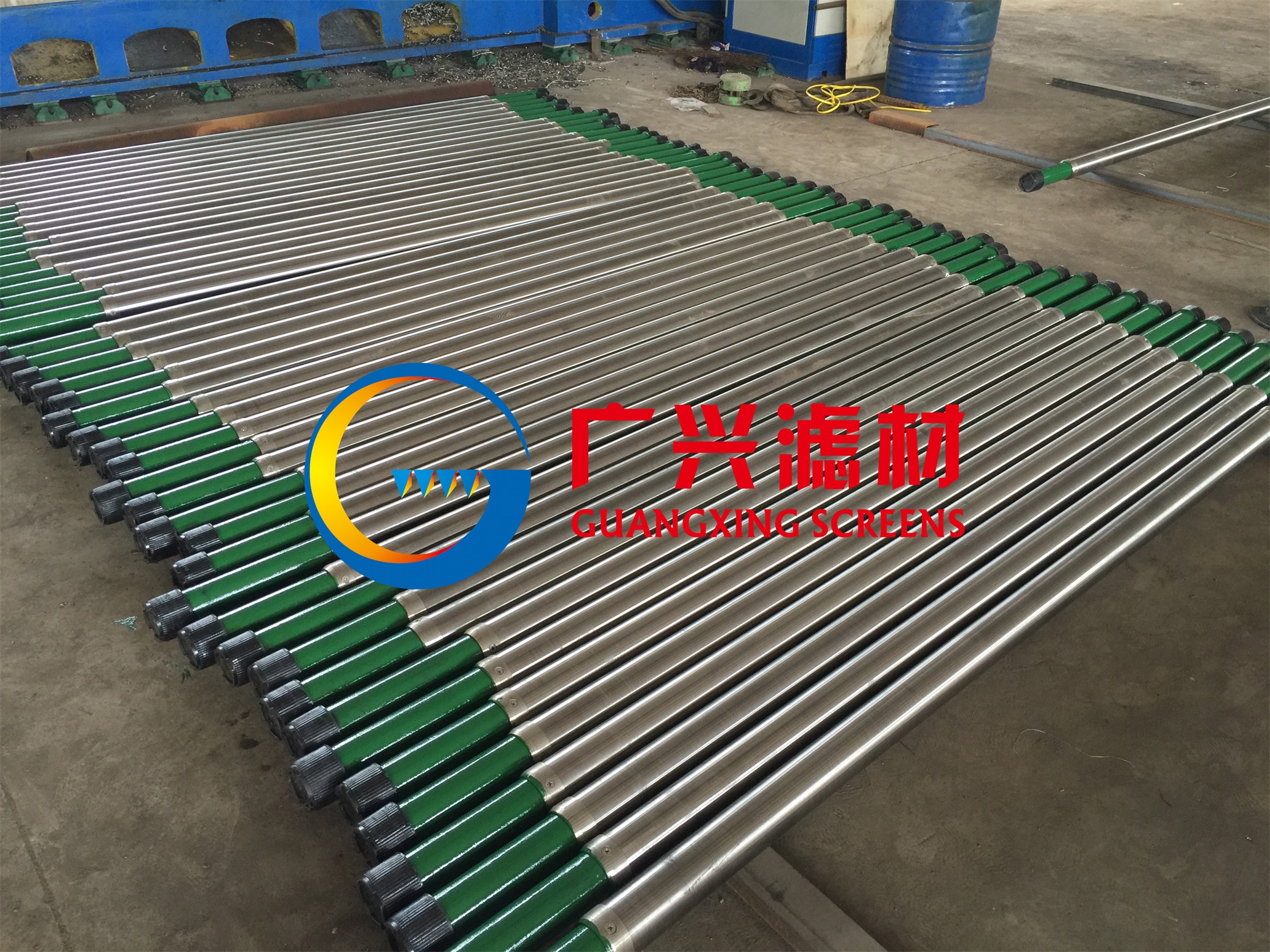

Slip On wire wrap screen is manufactured as a standalone jacket which is installed over a perforated base pipe and secured via welds on each end.

Slip On wire wrap screen

Slip On wire wrap screen is manufactured as a standalone jacket which is installed over a perforated base pipe and secured via welds on each end.

The wire wrap screen can be manufactured in multiple configurations based on customer requirements and application.

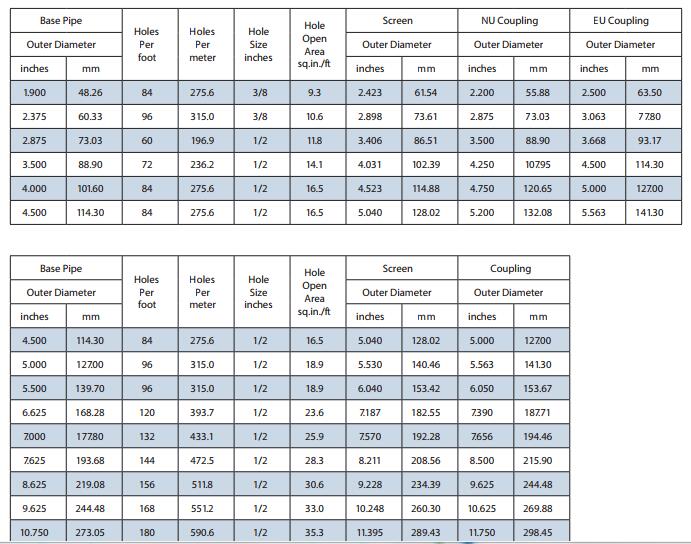

wire wrap screens are manufactured from 304L or 316L stainless steel. The screen gauge is strictly monitored throughout the wrapping process and qualified to the ISO 17824 wire wrapped screen standards; with optical gauge verification available. The base pipe is perforated maximizing open flow area, finding the optimal value to provide adequate inflow while minimizing the yield reduction of the pipe.

Features and Benefits

• 304L/316L Stainless steel Rib and Wrap Wires for optimized corrosion and plugging resistance

• High Open Flow Area 5%-20% based on Screen Gauge

• Increased well bore longevity and reduced work over costs

• Sand control is independent of the mechanical integrity of the liner

• Low entrance velocity with lower drag forces

• Proven design with hundreds of thousands of meters installed

• Keystone wrap wire to aid in self cleaning ability of screen Applications

• Thermal SAGD/CSS HZ open hole

• HZ cased hole

• Scab Liner installations for failed well bores

• InjectionWells

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier