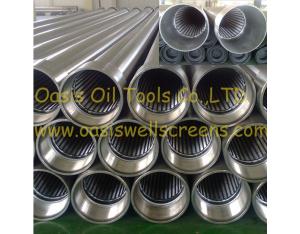

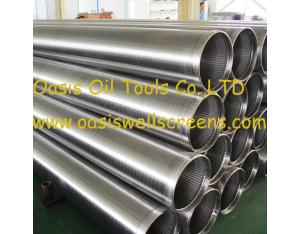

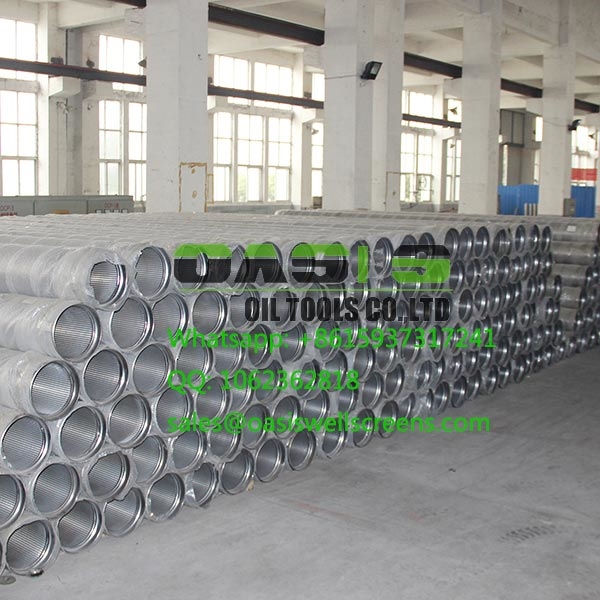

Continuous slot wire wrapped water well screens for water well drilling

- Product Details

- Company Profile

Continuous slot wire wrapped water well screens High quality Competitive price Timely delivery

Oasis Oil Tools Co.,Ltd is a professional manufacturer of water well screens, Johnson screens, wire wrapped well screens, continuous slot vee shaped wire well screens, wedge wire screens , oil well screens, bridge slotted well screens, rod based well screens, pipe based well screens, API casing, ISO tubing, steel pipe, steel tube.

China factory supply wedge wire wrapped water well screen

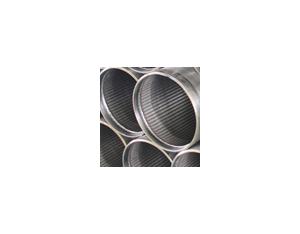

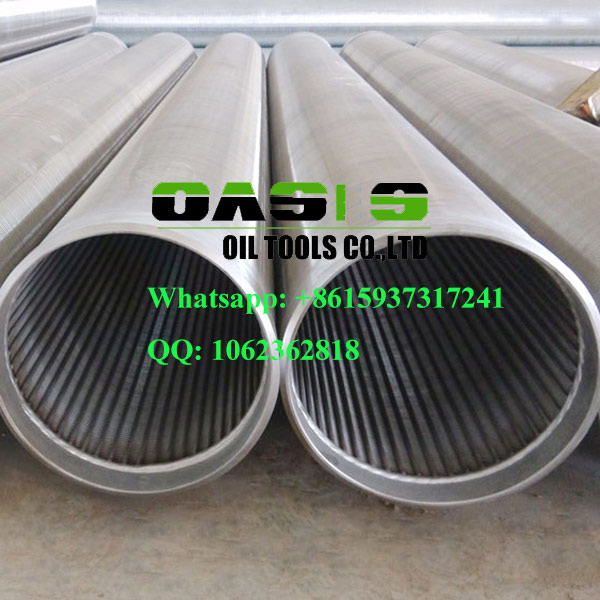

The v-wire wedge wire screen pipe is made up of rods and warp. The rod can be round wire,

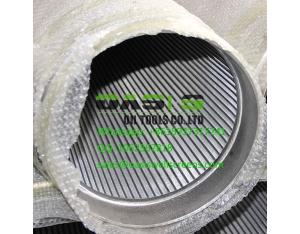

triangular wire or trapezoid wire.The warp is triangular wire (V-shaped wire). V-wirewedge wire screen pipes have a robust structure and large open area, as well as accurate slot dimension.

At the same time, V -wire water well screens have many advantages such as heat-resisting,

anti-corrosive, good machine capability,long service life, safety and reliability and so on. It can be used in many kinds of medium filtering.

Features of wedge wire wrapped water well screen

1.Screens with large open area are more suitable for the construction of high-quality water wells, oil wells and gas wells.

2. Low cost operation

Screens with large open area shall favor groundwater filtration. Abundant water will reduce the water level’s down, thus to save energy consumption.

3.Under the same condition, large open area can make the speed of groundwater’s enter into the screen much slower than any other filtration apparatus,

which will avoid sand entering into screen because of high pressure, which reduce the abrasion of the pump.

4. Extending the service life of wells

Comparatively, groundwater’s entering into screen with larger open area is much easier than that entering into smaller open area screen.

The slow water flow will extend the service life of the wells.

Advantage of wedge wire wrapped water well screen

·Continuous slot opening significantly increases the available open area, thus providing greater access to the water bearing zone.

· A “V”shaped profile wire avoids clogging and ensures an uninterrupted flow.

· V-wire welded screens have a robust structure and large open area, as well as accurate slot dimension.

· V-wire welded water well screens have the features of easy backwashing, long service life, high safety and reliability and competitive price.

Technical Information of wedge wire wrapped water well screen

| Wire Size | Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 | |

| Support Rods | Width(mm): 2.30 3.00 3.30 3.70 Height(mm): 2.70 3.60 4.70 5.60 6.30 Round: From 2.50mm to 6.0mm | |

| Note: other wires and rods available upon request | ||

| Slot size | 0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. | |

| Material: | Low carton, low carton galvanized steel (LCG), stainless steel (304,316 etc.) | |

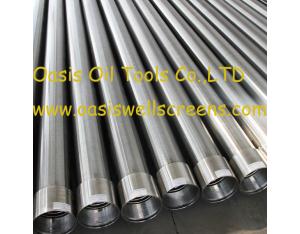

| Length | Lengths up to 6 meters. | |

| Diameter | ranging from 25mm to 800mm. | |

| End connection | Plain beveled ends for butt welding or threaded | |

Any needs for our johnson type water well screens, please feel free to contact me for more information.

.jpg)

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier