Twist off cap juice production line/Twist Off Cap Juice Filling Machine With liquid nitrogen filling

- Product Details

- Company Profile

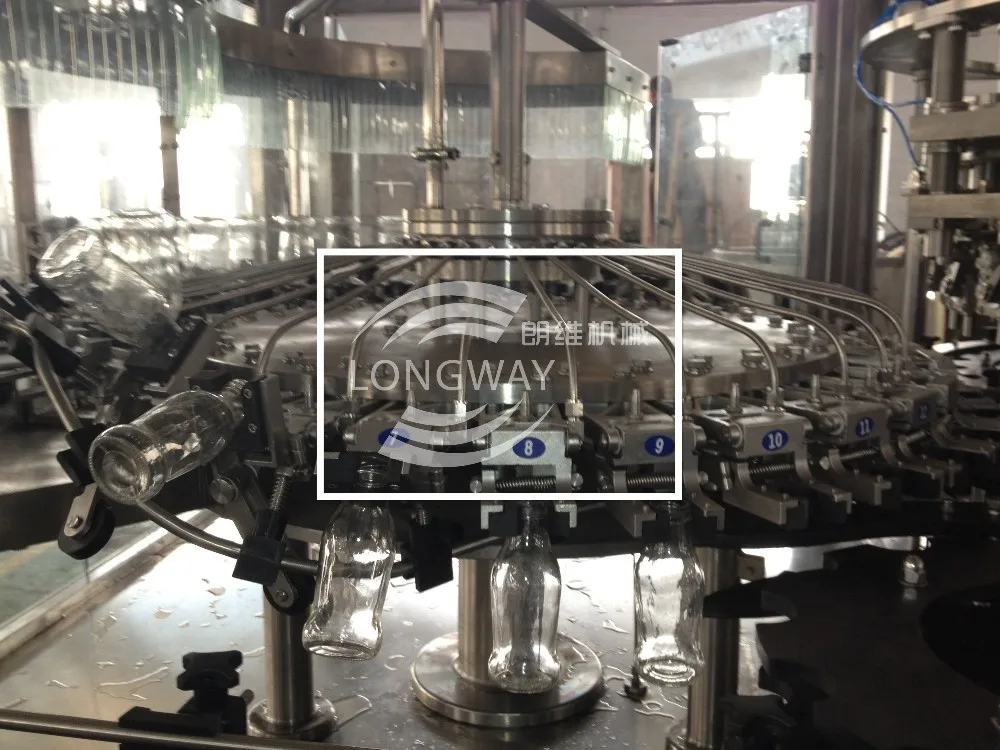

Twist off cap juice production line/Twist Off Cap Juice Filling Machine With The liquid nitrogen filling machine

Product Description

This Juice Filling Machine with famous electrical components and Food stage SS ,high performance and quality 15monthes guarantee

RCGF Juice hot filling 4-in-1unit

Products Introduction Usage:

RCGF series of Juice hot filling 4-in-1unit is introduced advanced foreign technology such as washing,pulp filling,juice filling capping technology. It is used in filling hot fruit juice, tea and other beverage, if you replace some parts, it can also be used in filling normal temperature filling.

Beverage Machinery-Equipment characteristics:

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change of the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, OMRON.

7. Equipped with a constant temperature system, temperature controlled and circumfluenting automatically.

| Model | RCGGF 16-8-12-6 | RCGGF 18-12-18-6 | RCGGF 24-18-24-8 | RCGGF 32-24-32-10 | RCGGF 40--32-40-12 | RCGGF 50--42-50-15 |

| Washing No | 16 | 18 | 24 | 32 | 40 | 50 |

| Filling No | -8-12 | 12-18 | 18-24 | 24-32 | 32-40 | 42-50 |

| Capping No | 6 | 6 | 8 | 10 | 12 | 15 |

| Production Capacity(500ml) | 5000BPH | 6000BPH | 8000-10000BPh | 12000-15000 BPH | 15000-18000 BPH | 18000-20000 BPH |

| Install Capacity(KW) | 3.5 | 4 | 4.8 | 7.6 | 8.3 | 9.6 |

| Overall size | 2450×1800×2400 | 2650×1900×2400 | 2900×2100×2400 | 4100×2400×2400 | 4550×2650 |

MAIN PARTS

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier