casting production line

- Product Details

- Company Profile

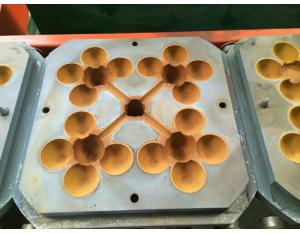

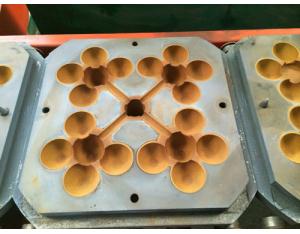

Condition:New Place of Origin: Anhui, China (Mainland) Brand Name: Zhicheng Model Number: ZZJX-F Voltage 380V Power(W) 100KW Dimension(L*W*H) 27m*8m*4m Weight 22T Certification: ISO9001:2008 Warranty:1 Year After-sales Service Provided Engineers available to service machinery overseas Type High Efficiency Feature Professional Name: casting production line Application: produce grinding balls;bent axle; brake drum ;water meter shell;hammer;form relieved tooth; steel talons Capacity: 3000~12000tons/year Molding machine: Shell Molding Machine

casting production line

Technological process:

preheat iron mould-------shoot sand to iron mould by core shooting machine------Checking iron mould with sand,adding and reduce sand if needed-------pouringmelting water-------open the mold and the grinding balls coming out-----clean out the residual sand------moulding again.

Function:automaticlly produce cast grinding balls used in mine;cement plant;power station;chemical industry;etc

Component:open mold machine;close mold machine;turnover machine;clean out residual sand machine;core shooting machie;reversing machine;pusher mold machine;blow sand machine;pouring machine;roll gang;etc

Advantage:

(1)Alternating with live and non-live roller,which makes the whole line operation smoothly.It can run normally even lacking of mould

(2)Only 3-4 people to operate the whole line

(3)The moulding line and pouring line realize the function of non-interfering,inter-supply and hoarding,stabilize and speed up the space of real-load running.

(4)The fasted speed of pouring line 25″

(5)Four size ball mould can run at the same time

(6)Providing far distance service by wifi,when there is electric damage on the device,the user can alarm and the display screen can show the mistake reason solving method.The operator can call our service center,our company can solve the damage by website,highly improve the quality of after sale service

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier