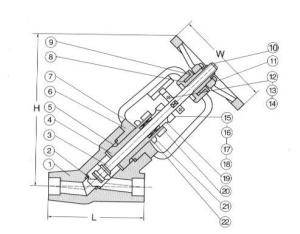

Y-pattern/Straight Through Globe Valve

- Product Details

- Company Profile

Datian forged steel Y-pattern globe valve are available in three bonnet designs. The first design is the Bolted Bonnet, with male-female joint,spiral wound gasket, made in F304/graphite. Ring joint gasket are also available on request. The second design is the welded bonnet with a threaded and seal welded joint. On request a full penetration strength welded joint is available. The third design is the pressure seal bonnet, with a threaded and pressure seal bonnet joint. The Y-pattern valves are available in globe and check design configurations.

Forged steel globe valves are designed and manufactured to provide maximum service life and dependability. Forged globe valves can be full port or reduced port as per requirements of customers. Valves are available in a complete range of body/bonnet materials and trims.

Applicable Standard

Design Standard: API 602, ASME B16.34, BS 5352, DIN3352

Face to Face: ASME B16.10, EN 558, DIN3202

End Flange: ASME B16.5, DIN2533

Butt welding Ends: ASME B16.25, DIN3239

Socket Welded Ends: ASME B16.11

Threaded Ends: ASME B1.20.1

Inspection and Test: API 598, DIN 3202

Products Range

Size: 1/2" ~ 2" (DN15 ~ DN50)

Rating: ANSI 150lb ~ 2500lb (PN 1.0 ~ PN 320)

Body Materials: A105,LF2,F9,F11,F22,F304,F304L,F316,F316L,F321,F51, Alloy Steel,etc.

Trim: Per API 602

Operation: Handwheel

Design Features

Full port or reduced port design

General or needle disc

Bolted bonnet, welded bonnet, or pressure sealed bonnet

Flanged, butt-welded, socket- welded, or threaded ends

Optional Y structure

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier