Forged Steel Check Valve

- Product Details

- Company Profile

Datian compact design, high pressure, Forged Steel Check Valves are designed and manufactured according to BS 5352 to meet requirements of small Pipelines up to 50NB. They are available either with Threaded or Socket Weld ends. Hard Faced Trim material ensures perfect Sealing and long life. Properly guided Lift type Disc which acts on its own according to flow direction. These Valves are generally suitable for horizontal installation.

Forged steel check valves are designed and manufactured to provide maximum service life and dependability. Forged check valves can be full port or reduced port as per requirements of customers. Valves are available in a complete range of body/bonnet materials and trims.

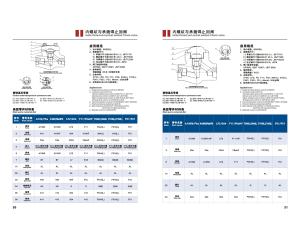

Applicable Standard

Design Standard: API 602, ASME B16.34, BS 5352

Face to Face: ASME B16.10, EN 558, DIN 3202

End Flange: ASME B16.5, DIN2533

Buttwelding Ends: ASME B16.25, DIN3239

Socket Welded Ends: ASME B16.11

Threaded Ends: ASME B1.20.1

Inspection and Test: API 598

Products Range

Size: 1/2" ~ 2"(DN15 ~ DN50)

Rating: ANSI 150lb ~ 2500lb

Body Materials: A105,LF2,F9,F11,F22,F304,F304L,F316,F316L,F321,F51, Alloy Steel,etc.

Trim: Per API 600

Design Features

Full port or reduced port design

Swing or Piston / lift type

Bolted bonnet, welded bonnet, or pressure sealed bonnet

Flanged, butt-welded, socket- welded, or threaded ends

Optional Y-type structure

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier