Trunnion Mounted Full Bore Three Pieces Ball Valve

- Product Details

- Company Profile

DATIAN trunnion mounted ball valves feature: a full line product offering with valves ranging in 2"-42", ANSI classes 150LB - 2500LB, forged steel bolted or all welded body, close coupled trunnion block design for low operating torques, secondary seat sealant feature.API-6D valves are offered with self relieving seats or optional double piston sealing. Special seat compounds are also available. Each valve meets, API-6D, API 6FA and Nace requirements. Options include stem extensions, actuators, pipe pups and specialized coatings.

Trunnion mounted ball valve is widely used in oil, nature gas pipeline and the industries of liquefied gas, coal gas, etc. as an open/close control element. The design of seat seal uses unique two-level soft seal and metal to metal seal to form triple sealing to ensure seal reliability with small open/close torque and easy operation. So it is safe and free of maintenance to use this series of ball valve. This type of valves has advantage of less weighted and cost effective. It is ideal for frequent on-off flow control in big size and high pressure pipeline.

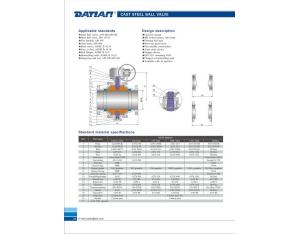

Applicable Standard

Design Standard: API 6D, ASME B16.34, BS 5351, API 608, MSS SP-72

Face to Face: ASME B16.10, API 6D, EN 558

End Flange: ASME B16.34, DIN 2501

Buttwelding Ends: ASME B16.25

Inspection and Test: API 598, API 6D

Products Range

Size: 2" ~ 48"(DN50 ~ DN750)

Rating: ANSI 150lb ~ 1500lb

Body Materials: Carbon steel, Stainless steel

Trim: A105+ENP, 13Cr, F304, F316

Operation: Lever, Gear, Electric, Pneumatic, Hydraulic actuators

Design Features

Full port or reduced port

Trunnion mounted ball

Blowout-proof stem

Double block & bleed

Emergency sealant injection

Cavity pressure self relief

Fire safe design to API 607 / API 6FA

Anti-static to BS 5351

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier