Cast Steel Floating Ball Valve

- Product Details

- Company Profile

Design Features DATIAN standard floating ball valves are manufactured in tow pieces bolted body,ball valves could be supplied full or reduced bore,designed for maximum rigidity against pipeline thrust,made from forged components or barstock. Bolted body constructions allow easy service and maintenance opration on site,Pressure rating is from class ANSI 150 up to ANSI 2500 Lbs. Valves are usually supplied with lever operator,with gear box or bare stem on customer request.All standard floating ball valves have below features: Lock device:valve is equipped iwth an integral locking device to secure line flow. Blow-out proof stem:the stem is made separately from the ball with integral T-type round shoulder,which ensures total safety and integrity. Anti-Static Design:grounding device are supplied form positive anti-static between ball/stem and body. ISO 5211 mount plate:simplifies the installlation of actuators with standard connections. Emission-firee gasket:the primary gaskey is emission free graphite to eliminate leakage.

Floating ball valves mainly apply to the industries of nature gas, oil products, chemical industry, metallurgy, city construction, medicine, environment, foods, etc. as on /off control units. Its body is made of casting or forging; the ball is floating, the ball moves (floats) downstream to maintain close contact with downstream seat to form a reliable seal under the medium pressure when closes. The seat special design has the wearing complementary structure to ensure safe reliable sealing and long stable operation of this series of ball valve. It has the merits of sealing reliability, long life cycle usage and easy operations.

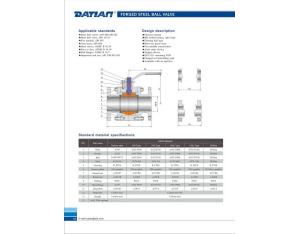

Applicable Standard

Design Standard: API 6D, ASME B16.34, API 608, BS 5351, MSS SP-72

Face to Face: API 6D, ASME B16.10, EN 558

End Connection: ASME B16.5, ASME B16.25

Inspection and Test: API 6D, API 598

Products Range

Size: 1/2" ~ 10" (DN15 ~ DN250)

Rating: ANSI 150lb, 300lb, 600lb

Body Materials: Carbon Steel, Stainless Steel, Alloy Steel

Trim: A105+ENP, 13Cr, F304, F316

Operation: Lever, Gear, Electric, Pneumatic, Hydraulic

Design Features

Full port or reduced port

Floating ball design

Blowout-proof stem

Casting or forging body

Fire safe design to API 607/ API 6FA

Anti-static to BS 5351

Cavity pressure self relief

Optional locking device

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier