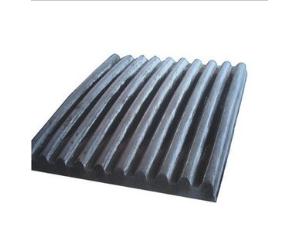

high manganese steel casting/ manganese steel casting

- Product Details

- Company Profile

Real factory, with more than 10 years' experience in casting.

Basic Info.

Material :Manganese steel, high manganese steel Place of Origin: Shanxi, China (Mainland)

Brand Name: QINGHUI Dimensions :as Buyer′s Drawing

Surface: Polishing, Plating, Shot Blasting, Heat Treatment Delivery: Within 30 days

Execution Standard: ISO9001:2008,ISO/TS16949:2009 , SGS

Export Markets: North America, South America, Eastern Europe, Western Europe

Additional Info.

Trademark: QINGHUI or OEM Packing: Wooden Box

Standard: ASTM or as your request Production Capacity:20000 pc/month

Product Description

Advantage

1. Real factory, with more than 10 years' experience in casting.

2. Your inquiry will be replied within 24 hours.

3. Well-trained and experienced staff to answer all your enquiries in fluent English.

4. Strict quality control process to guarantee all the products to our customer is qualified.

5. OEM&ODM, any of your customized casting items we can help you to design and put into product.

FAQ

Q: Are you manufacturer or trader?

A: We are a manufacturer for more than 10 years' experience in casting.

Q: What is your MOQ?

A: That depends, but small order quantity is also acceptable.

Q: How long is the lead time for mass production?

A: Normally 10-30days, but depends on the exact product.

We manufacture metal parts in compliance with customers' design.

The products shown here are only to present scope of our manufacturing activities and are not for sales.

Welcome to your inquiries.

| Process available | silica sol, sodium silicate (soluble glass) and compound process |

| Material available | Duplex stainless steel, stainless steel, carbon steel, Alloy Steel, and etc. |

| Standard | ISO9001:2008, ISO/TS16949:2009, SGS, ABS |

| Product | all kinds of casting(unit weight ≥0.1kg) |

| Surface finish | Passivation,polishing or as your request |

| Applied software | Pro/E, Auto CAD, Solid Work 2001,CAXA, UG, CAD/CAM/CAE |

| Production capacity | more than 2,000MT per year |

| heat treatment: | anneal, quenching, normalizing, carburizing,polishing, plating |

| Machining | CNC and NC machining, turning, milling, drilling, boring, threading, grinding machines and test facility |

| Certification | ISO9001:2008, ISO/TS16949:2009 |

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier