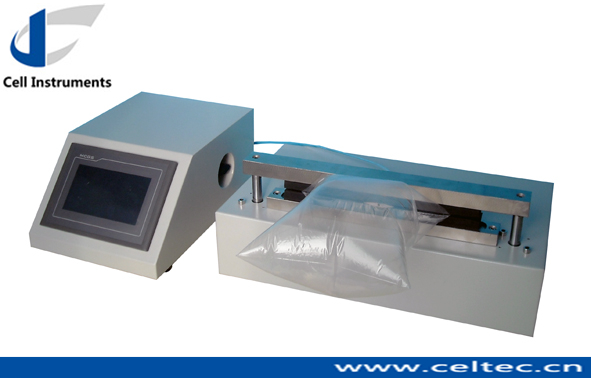

Leak and Seal Strength Tester

- Product Details

- Company Profile

Leak and Seal Strength Detector is suitable for the quantitative determination of sealing strength, heating sealing quality, burst pressure and leakage of flexible and aseptic packages. The Leak and Seal Strength Detector can also be used to determine the sealing performance of pilfer-free bottle caps and soft tubes. The compression strength, connection strength of cap and body, cap losing strength, seal strength and butting strength of tubes are the applications .

The three test modes of the positive pressure method, which Leak and Seal

A. Burst Test: It internally pressurizes the packages until the package fails. The test pressure is the maximum pressure detected before the package fails.

B. Creep Test: Pressurize the package internally to a specific pressure and maintains this pressure for a specific time. The test measure is pass/fail.

C. Creep to Failure: The package is creep-tested and held until the package fails. The pressure setting is higher than that of the creep test to ensure the package fails in some time. The measure is the time until failure.

Features

1. Three test modes of burst, creep and creep to failure are available.

2. PLC programmable logic controller realizes precise pressure and time control.

3. 7 inch TFT touching screen for convenient parameter setting and test operation.

4. Multiple groups of test parameters can be save to avoid repetitive setting.

5. Test result auto statistics and storage.

6. Program customization available.

Technical Specifications

Pressure Range 0 ~ 600 KPa; 0 ~ 87.0 psi (Standard)

Inflating Head Φ4mm (Standard)

Gas Pressure 0.4 MPa~0.9 MPa

Port Size Φ6 mm PU hose

Dimensions 400 mm (L) × 270 mm (W) × 180 mm (H)

Pedestal Size 375 mm (L) × 275 mm (W) × 345 mm (H)

Standards

ISO 11607-1, ISO 11607-2,ASTM F1140, ASTM F2054, GB/T 10440, GB 18454, GB 19741, GB 17447, GB/T 17876, GB/T 10004, BB/T 0025, QB/T 1871, YBB 00252005, YBB 00162002

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier