European Double Girder Overhead Crane

- Product Details

- Company Profile

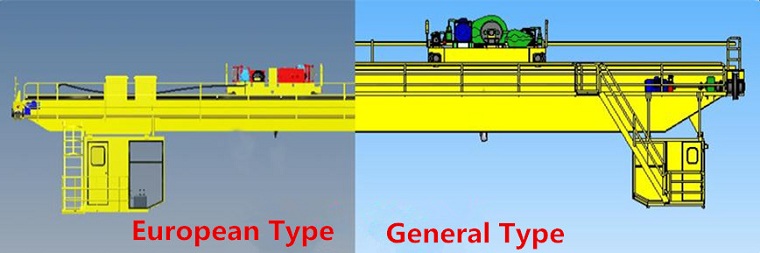

European Double Girder Overhead Crane is based on modular design theory and modern computer technology, using new materials, new technology completed new bridge crane with high degree of commonality, intelligence and high-tech.

European Double Girder is based on modular design theory and modern computer technology, using new materials, new technology completed new bridge crane with high degree of commonality, intelligence and high-tech.

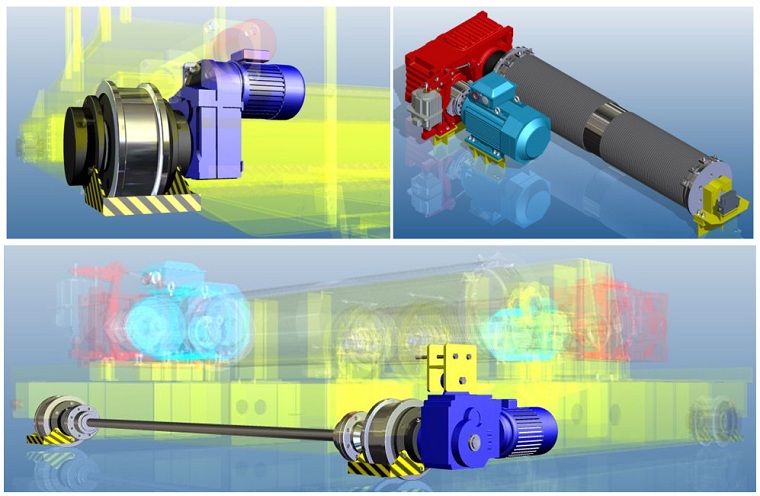

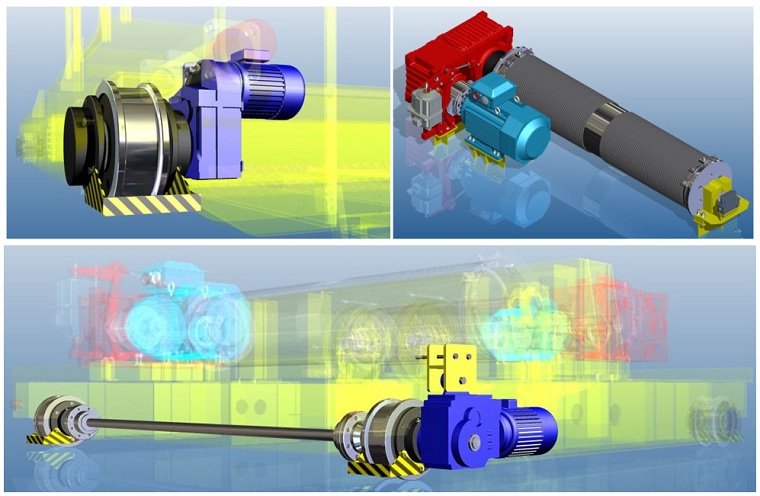

design and manufacture in strict accordance with FEM and DIN standard. It is with compact structure, large operating range, using holistic processing, with high precision. Hoisting mechanism including two forms: winch trolley and electric hoist trolley. Using hardened three-in-one motor, reducer, with compact layout and smooth operation. Particularly suitable for large-tonnage precious objects lifting and handling in position.

has the following advantages compared with the traditional crane:

1. Low height, light weight; small hook limit, large operating range.

Compared with general type bridge crane, crane weight reduced by 15% to 30%, wheel pressure reduced by 15% to 30%, crane height reduced by 20 ~ 30%, which greatly reduces the cost of the plant.

Trolley with compact design, can achieve smaller upper, left and right limits of the hook, greatly increasing the hook work scope.

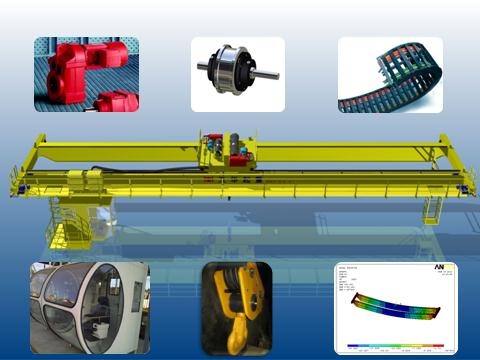

2. Selection of high-quality components, less maintenance work; mechanisms take finite element analysis, which is safe and reliable.

The crane adopts three-in-one hardened motor and reducer, using steel rolled overall annealing treatment drum group, use of 65Mn forged wheel set, using engineering towline conductive, and crane operation is more safe and efficient.

Steel structure take finite element analysis, to ensure that the crane with lightweight structure, safe and reliable.

Each transmission mechanism adopts direct coupling type, reducing transmission links and failure points, improve transmission efficiency, reduce crane energy consumption.

4. Overall Processing, High precision.

Forged wheel set, machining boring assembly.

Overall processing trolley frame after welding, with small welding distortion and high assembly precision.

Overall processing end beams after welding, with small welding deformation and high assembly precision, which will help overhaul.

5. Frequency control, smooth start and braking; hook can adopt anti-sway technology, safer lifting.

All mechanisms using frequency control, smoothly start and braking without impact, increasing security of crane operation and improve productivity.

Electrical anti-sway function can be selected: no swing while hoisting object, precise positioning and automatic reset, improve work efficiency and safety.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier