Single-stage Crusher

- Product Details

- Company Profile

Single-stage crusher can directly crush materials with particle size of 600-1800 mm to 25 or 25 mm, mainly used for crushing in building materials, mining, chemical and other departments crushing brittle and medium-hard materials, and materials with low moisture content such as limestone, rock and so on. Compressive strength of the material should be not more than 140 MPa. Single-stage crusher has large crushing ratio, low power consumption, small footprint, easy maintenance and other features.

Feeding Size: ≤800 - ≤1250 mm

Product Size: <3-8 mm

Capacity: 100 - 420 t/h

Power: 160 - 630 kw

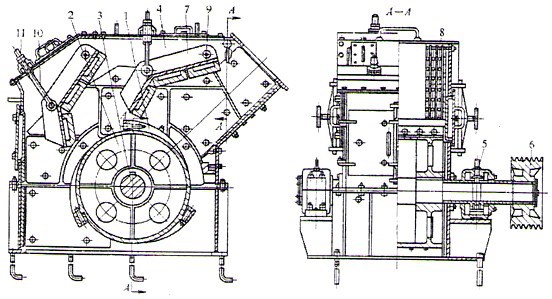

Single-stage Crusher Introduction:

Single-stage crusher can directly crush materials with particle size of 600-1800 mm to 25 or 25 mm, mainly used for crushing in building materials, mining, chemical and other departments crushing brittle and medium-hard materials, and materials with low moisture content such as limestone, rock and so on. Compressive strength of the material should be not more than 140 MPa. Single-stage crusher has large crushing ratio, low power consumption, small footprint, easy maintenance and other features.

Single-stage crusher can crush the giant materials to the size that grinding needs. Thereby, it took the place of the traditional two-stage crushing to simplify processes and reduce production costs. the crusher is mainly used in the production of cement, sand and gravel aggregate production and other large-scale projects

Single-stage Crusher Features:

1. Large breaking ratio, with maximum feeding size up to 1.3-1.5m;

2. Adjustable particle size range of 3-150mm;

3. Good aggregate grain shape, powdery material ≤ 20%;

4. Work simplification can simplify the original two-stage or three-stage crushing to one-stage crushing;

5. Low operating costs, small power greatly reduces the production cost.

Single-stage Crusher Working Principle:

After materials go into the crushing chamber, they will pile up on the middle bracket specially set inside the machine. The hammers run between the gap of the middle bracket and continuously crush the materials that will fall down. The falling small-sized materials will be further impacted and crushed by the hammers running with high speed, and finally the materials will be discharged from the bottom.

| Model | Type | Rotor diameter | Feeding size (mm) | Product Size (mm) | Capacity (t/h) | Power (kw) |

| DPC140 | Single Rotor | 1400 | ≤800 | <3-8 | 100-140 | 160-220 |

| DPC160 | 1600 | ≤1000 | 150-240 | 280-355 | ||

| DPC200 | 2000 | ≤1250 | 330-420 | 500-630 |

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier