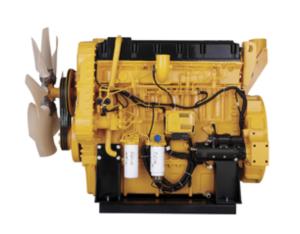

Industry Engine - KD6121ZL

- Product Details

- Company Profile

Product Description * Overhead Cam * Four valves per cylinder, * Exhaust turbocharger * Air to air Intercooler * Electronically controlled in line fuel pump * Electronic governing system

Strict Quality Control of KIPOR New Generation Engines

Emulation technique is widely applied to ensure the engine performance since the design phase.

KIPOR invested many advanced testing facilities of engine.

Various strict testing performed to the components and engine itself to ensure the final quality.

Benefits of KIPOR New Generation Engines

Low Fuel Consumption

Lower Operating Costs

Electronic control of the combustion process and high thermal efficiency rating.

Simplified Service and Maintenance Work and Longer Service Intervals

• Oil change at 500 hour intervals (normal operating conditions)

• Filters grouped for ease of service and maintenance

• Easy access to engine installation for service and maintenance

Low Emissions

Reduces nitrogen oxide (NOx) emissions by over 50%

After treatment system consisting of an Oxidation Catalyst and diesel particulate filter reduces particulate matter emissions by 90%

Maintenance Free Crankcase Breather Separator.

Low exhaust emissions meets current exhaust emission legislation (US Tier 3/EU Stage IIIA)

Reliability

Robust structures keep the moving parts running smoothly throughout the engine life

The latest premium sealing technologies prevent any fluid leaks .

Low Noise (89dba at 1m max) – Makes Your Machine Operator’s Life Easier

A rigid bedplate reduces vibration and noise generation whilst a rear geartrain further reduces noise output

No metal-to-metal contact between engine and covers isolates them, again reducing vibration and noise

Laminar steel oil pan has a cushioning effect to deaden sound

CCCME Member

CCCME Member 0

0 Chinese

Supplier

Chinese

Supplier