Aluminium Copper and Bimetallic type

- Product Details

- Company Profile

Type No.:MAG-Aluminium Copper and Bimetallic type

| Application | Features and benefits | |

| For bare overhead aluminium or copper tap conductors. | Bodies in high strength aluminum alloy(AIMgSi) or electrolitic copper | Uniformity of material Long term elasticity Corrosion withstand |

| Description | Pressure pad | Uniform pressure along the clamp |

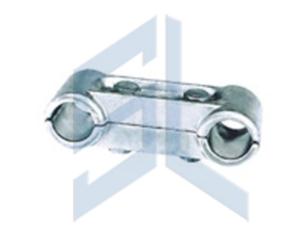

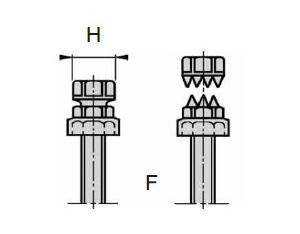

| Parallel groove clamps are mainly used for transmitting current between the interconnected conductors, for example for connection loops on terminal poles or tapping off bus-bars to equipment on substations. From this function it is therefore obvious that the electrical conducting properties and the corrosion resistance are the main factors for consideration in the design. Besides this main area of application parallel groove clamps are also used for safety loops and therefore they must provide an adequate mechanical holding strength. If conductors made of different materials are to be connected this can be done by using bimetallic tubes. This range of connectors is designed to connect two paralell conductors in order to do a derivation of a secondary conductor, or to close a loop of one conductor to fit it on an insulator. These connectors are composed of two parts : Upper body and lower body, they have two paralell grooves to receive the conductor(s).One, two or three bolts are passing throught the bodies between the grooves. In aluminium clamps, the two bodies are made out of high strength aluminium alloy. In copper clamps, the bodies are made out of high strength electrolitic copper. In bimetallic clamps, the two bodies are made out of high strength aluminium alloy, and to tight a copper conductor, one groove is made with allumiunm alloy and welded by hot forged bimetallic sheet . The bolts are made out of hard steel (8.8) and Dacromatized. To warranty a reliable tightening, a pressure pad and a spring washer are inserted under the bolt head. | Spring washers | Maintain the pressure even if a temperature change causes dilatation |

| Dacromatized steel bolt 8.8 | High permanent strength applied on the clamp | |

| Hot forged compressedbimetalic sheet (in bimetallic clamps) | Good electrical contact without corrosion | |

| Ridged grooves (forged type only) | Improve mechanical pullout strength and electrical contact | |

| Holding strength | An adequate mechanical holding strength is achieved. In case of higher values two or more PG-clamps should be used in series. | |

| Corona | Good corona and radio interference voltage (RIV) behavior due to rounded shapes. | |

| Corrosion resistance | Maximum corrosion resistance is achieved by using a clamp material that matches with that of the conductor, for example a corrosion-resistant AlMgSi alloy for conductors made of aluminium, al-alloy etc. | |

| The requirements will be fulfilled and demonstrated by heat cycle tests. Overhead Lines | ||

| Option Can be equipped of shearhead bolts. | ||

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier