Energy Saving IGBT Induction Furnace 1ton

- Product Details

- Company Profile

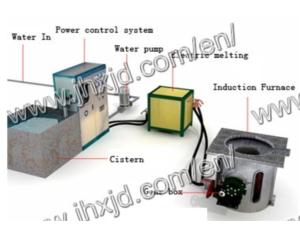

Energy Saving IGBT Induction Furnace, mainly used in melting iron, steel, stainless steel, and alloy, is with high melting efficiency, good electricity saving effect, good metal component uniformity, less burning loss, speedy temperature rise, easy contr

1.Production Name: Energy Saving IGBT Induction Furnace 1ton

2.Production Description:

| Furnace Model | GW-IGBT-1T-700KW/1S | |

| Rated Capacity | T | 1 |

| Max. Capacity | T | 1.3 |

| Rated Power | KW | 700 |

| MF Frequency | KHZ | 1 |

| Power Input Voltage | V | 380 |

| MF Output Voltage | V | 750/1200 |

| Melting Rate | T/H | 1.5 |

| Melting Time | Minutes/batch | 55 |

| Electricity Consumption | KWH/T | 510 |

| Transformer Capacity Required | KVA | 900 |

| Water Cooling Consumption | T/H | 25 |

3.Usage: Energy Saving IGBT Induction Furnace, mainly used in melting iron, steel, stainless steel, and alloy, is with high melting efficiency, good electricity saving effect, good metal component uniformity, less burning loss, speedy temperature rise, easy control of temperature, is suitable to all kinds of metal melting.

4.Characters and Advantages:

1) Constant power output, speedy melting, good electricity saving efficiency.

2) Zero-voltage sweep-frequency style start, adapts to requirement of frequently start.

3) Comprehensive protection functions, such as overcurrency protection, overvoltage protection, current-limiting protection, voltage-limiting, water-break protection, and default protection, equipment runs reliably under premise of melting speed guarantee.

4) Easy to operate, suitable for all casting process.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier