Angular Contact Ball Bearing

- Product Details

- Company Profile

Angular Contact Ball Bearings: 1 Large quantity in stock. 2. Quality guaranteed. 3. Widely used. 4. Competitive price

Product Description

Angular Contact Ball Bearings (7000C 7200C 7300C C and AC Series)

1) Good performance

2) Low noise, long service life

3) Competitive price

4) Prompt delivery

Structure: Angular Contact Ball Bearing

Type: Ball Bearing

Brand Name: KG, C&U, ZWZ, HRB, LYC, or OEM service.

Bore Size: 10 - 200 mm

Outside Diameter: 22 - 420 mm

Model Number: 70000C series

Precision Rating: P0 P6 P5 P4 P2

Seals Type: Open

Number of Row: Single Row

Place of Origin: Shanghai, China

Bearing type: Angular Contact Ball Bearing

Material Bearing: Steel GCr15, Stainless Steel

Raceway type: Spherical

Rolling body: Ball

Bearing cage: Bearing steel, Brass, Ceramic, Steel

Service: OEM

Performance: Low noise and Long service life

Port: Shanghai &Qingdao

Standard: National standard or we could produce by our customers' drawing

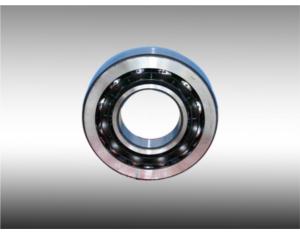

Thrust angular contact ball bearing are able to support radial load and axial load. As single row angular contact ball bearings can only support axial load in single direction, matched bearing mounting is often adopted to them. As matched pair of bearings, preload for them is more convenient. Retainer are made of brass, synthetic resins or others subject to individual bearing features and application conditions.

1). Main structure

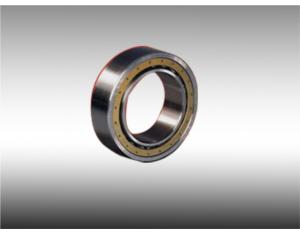

A. Single-row angular contac ball bearing

Single-row angular contac ball bearing have separable and non-separable designs, such as S7000 series and SN7000 series.

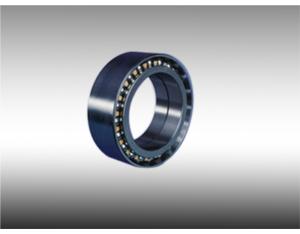

B. Double-row angular contact ball bearing.

C. Paired and match angular contact ball bearing.

2). Allowed angle of inclinnation

2). Tolerance and clearance

Other angular contact ball bearing information:

An angular contact ball bearing uses axially asymmetric races. An axial load passes in a straight line through the bearing, whereas a radial load takes an oblique path that tends to want to separate the races axially. So the angle of contact on the inner race is the same as that on the outer race. Angular contact bearings better support "combined loads" (loading in both the radial and axial directions) and the contact angle of the bearing should be matched to the relative proportions of each.

The larger the contact angle (typically in the range 10 to 45 degrees), the higher the axial load supported, but the lower the radial load. In high speed applications, such as turbines, jet engines, and dentistry equipment, the centrifugal forces generated by the balls changes the contact angle at the inner and outer race. Ceramics such as silicon nitride are now regularly used in such applications due to their low density (40% of steel). These materials significantly reduce centrifugal force and function well in high temperature environments. They also tend to wear in a similar way to bearing steel_rather than cracking or shattering like glass or porcelain.

Most bicycles use angular-contact bearings in the headsets because the forces on these bearings are in both the radial and axial direction.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier