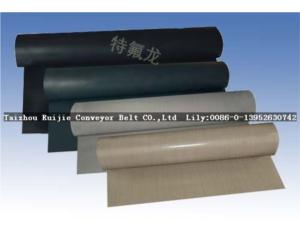

PTFE Seamless Heat Sealing Belt

- Product Details

- Company Profile

Our Belts are used to facilitate the flow of materials through various packaging cycles and are used in the following applications

Our Belts are used to facilitate the flow of materials through various packaging cycles and are used in the following applications:

Non-stick covers for heat-sealing units

Conveyors in packaging cycles

Conveyors in container manufacture

Release tape for protection of heat-sealing wires and jaws in shrink-wrapping operations.

Release fabric and tape for blister pack packaging

Release belts for sealing of the side and base of plastic wrapped packaging

Release belts for shrink-wrap ovens

Fabric for curtains for shrink-wrap ovens

Release tape for vacuum packing operations

Release tape for vertical form fill sealing

4). Plastics

RC(PTFE coated fiberglass fabrics) and RC(PTFE coated fiberglass tape) have been widely accepted as material handling aids in the Plastic Industry.

Precision Coating's products are suitable for a variety of diverse applications in this industry because of the following properties:

Smooth, non-stick surface

Temperature resistivity (-140~350)

Chemical resistivity

Durability

Heat transfer

Flexibility

Non-absorption

Dimensional stability (Belting)

Open weave

5). Rubber Extrusion

The rubber industry makes extensive use of the desirable properties inherent in Precision Coating's products. RC PTFE coated belts are also regularly used to carry rubber extrusions through the rigorous curing process. The ability to withstand radical temperature change without sacrificing basic product integrity make these belts extremely valuable in this application.

The following properties make this product line ideal for applications, such as Elecrical Oven Foil, Electronical Insulant tape, Curing Oven Sheet, Pizzas/cakes oven film, release blankets and curing of extruded rubber profiles, paint chips, PU, PE, and PVC Products:

Smooth, non-stick surface

Chemical and Temperature resistivity -100F to 500F (-73C to 260C)

Durability and dimensional stability

Porosity

Open weave

Fabric impression

Semi-conductivity.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier