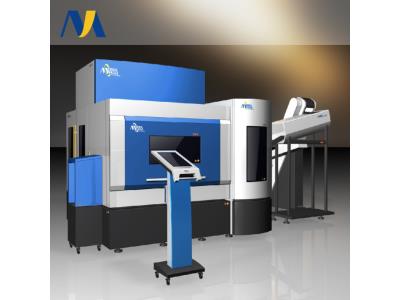

MG-E Economical Blow Moulding Machines

- Product Details

- Company Profile

MG-E Economical Blow Moulding Machines

BRIEF INTRODUCTION

Mega has rich experience to design various reheat stretch blow moulding equipments. After years of R&D, now we introduce the latest economical stretch blow moulding machine to the market. The MG-E is an economic two stage automatic stretch blow moulding machine, which is mainly designed for the PET and PP stretch blow bottles. The MG-E consumes less power due to optimized machine layouts and patented perform heating system, so the end of user can achieve maximum profit in today’s competitive bottle moulding market.

Overview

* Controller system

The new microprocessor has more storage memory; it saves the operating setting up to 30 sets. Re-programmed software detects any possible errors permitting immediate identification and diagnosis of the problem.

* Preform Feed

The preform stocked in the hopper are transported by conveyor and are sorted neck upwards for the feed ramp in to the perform oven automatically, the performs are now read to enter the oven equipped with its infra-lamps.

* Linear transport oven

The heating of the performs is optimized by the new modular oven with 9 layers of heating lamps. It guarantees the ideal temperature for quality blowing. The preforms self rotated by frictional belts during the continuous movement. Due to the small gaps between the preforms, it requires less electric costs. we called as economic running.

* Spacing unit

Thanks to the spacing unit. It is the key to guarantee the flexibility in bottles sizes and ensures the possible of small pitch at the oven section.

* Blowing station

Improved blow station fits with the blowing molds up to 2.5L. Thanks to the compensation unit, the new speedy clamping system allow you to blowing the bottles with pressure up to 40 Bar with perfect parting line on the bottles. And another major benefit is the fast mold changing over time.

Options

* PID system for heating zone

An Infrared thermometer detects the temperature of the preforms and automatically adjusts the temperature of the oven to the correct level. It avoids the influence of the temperature difference between day time and night time. Also, the system can have an additional lamp alarm unit, It sounds when it detects any broken or aging lamps.

* Air Recovery system

We know most of the production cost comes from two factors, blowing the bottles and reheating the performs . In order to reduce the production cost for the bottler producer, Mega has introduced an Air recovery system. This system recovers up to 30% of exhausted High pressure air.

* Air cooling system

hanks to our GM Cai Yuansen , we have developed an air cooling system for hot fill PET bottles, after high pressure blowing, air cooling is introduced. This reduces the level of PET residual stress, and increases the rate of PET crystallization. After the air cooling process, the PET bottle can stand hot filling without deformation.

Bottle SamplesPET bottles produced by MG-E series machine:

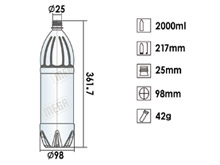

CSD-PET-bottle-2L

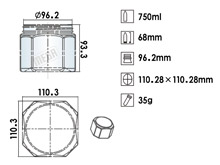

Jar-750ml

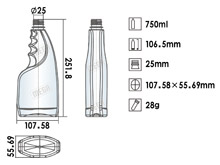

Detergen-750ml

Pharmacal-bottle 135ml

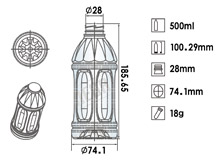

Hot-fill-500ml

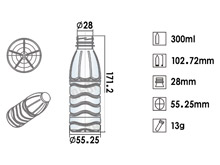

Water-bottle-300ml

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier